About Xtproto: Building Your Innovative Future

Xtproto specializes in the production of prototype and series production parts in a wide range of materials. With our own production facilities, we can provide you with the highest quality components and monitor the entire manufacturing process. We support you from staged prototyping to small series production to ensure continuous smooth procurement. We firmly believe that close cooperation with our customers is essential to meet your expectations.

Who are we?

We are an extension of your team

We are a turnkey solution for companies that need hardware. Whether the goal is prototype testing or mass production of mature products, Xtproto can effectively meet this need. We specialize in the field of custom processing. By providing a variety of manufacturing and engineering services, we can minimize the risks in project management, which is an important aspect to reduce the problems that arise when working with multiple companies to manufacture parts.

Unlike many custom processing companies, Xtproto can assist customers with part manufacturability analysis as well as project management. As a result, our team is able to share project management tasks and oversee production while our customers grow their business.

What makes Xtproto different from its peers is that we are well-known for design for manufacturability and assembly, also known as DFM and DFA, which is the application of rapid prototyping verification to help improve product design and manufacturing early in the development of customers’ products. These practices are designed to increase ease of manufacturing, thereby reducing costs, shortening production time and minimizing errors in the production process.

What do we do?

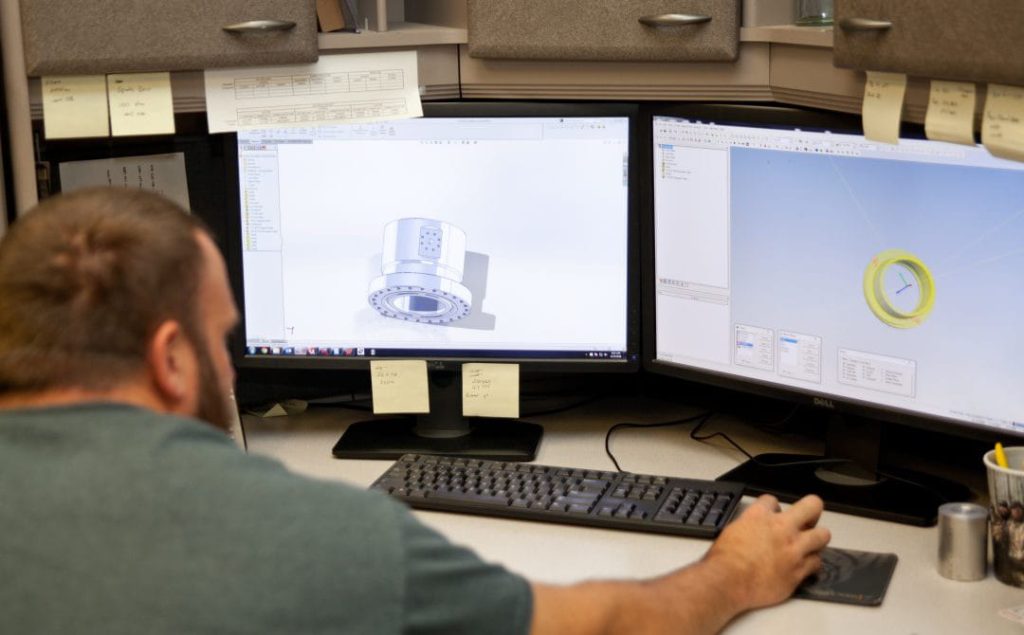

At Xtproto, our team of dedicated engineers specializes in helping customers manufacture parts using a variety of manufacturing technologies. Our team is always at the forefront of industry trends, blending new ideas with expertise.

We pride ourselves on being able to provide a comprehensive one-stop solution for your manufacturing needs. Whether it’s prototyping, low-volume production or high-volume manufacturing, we offer a wide range of manufacturing services to meet every need. From CNC machining, injection molding and sheet metal fabrication to 3D printing and more, our extensive manufacturing capabilities cover a wide range of industries and applications.

Xtproto’s strength lies in our strong manufacturing capabilities. With the latest technology, advanced equipment, our own factories and a global manufacturing network, we ensure that every project is built with exceptional precision and efficiency. With a team of highly skilled engineers and state-of-the-art facilities, Xtproto ensures a seamless transition from concept to final product, saving our customers time, effort and resources.

Our Vision: Empowering Innovators to Create

Our Mission: Simplify Procurement for Custom Manufacturing

An Internet Custom Manufacturing Services Company

At Xtproto, we are committed to providing customers with an excellent manufacturing experience, combining cutting-edge technology tools with on-site guidance from engineer experts and instant access to fully optimized manufacturing capabilities through our network. As a result, our customers achieve unprecedented manufacturing speed, quality, transparency and cost-effectiveness.

Reduce global supply chain risks

We support your full set of bills of materials with the speed, precision and quality you need in the most cost-effective way, helping you bring your products to market faster. Xtproto can provide guidance expertise worldwide to support rapid iterations, thereby reducing your product design risks and supply chain risks.

Core Values

Xtproto’s core values are the fundamental behaviors that everyone should follow, ensuring that our professional behavior is responsible and consistent.

Agile and Efficient

Xtproto values fast decision-making and streamlined processes. We prioritize rapid response and efficient operations to meet customer needs and effectively adapt to market changes.

Customer Oriented

At Xtproto, we focus on providing excellent customer service. We tailor solutions to our customers’ specific requirements to ensure customer satisfaction and long-term partnerships.

Teamwork

We believe in the power of collaboration. Our teams work closely across departments to share knowledge, solve problems and achieve collective goals, creating a supportive and efficient environment.

Passion for Innovation

Innovation drives Xtproto’s success. We continuously explore new technologies and innovative solutions to stay ahead of the industry, constantly push boundaries and provide excellent manufacturing services.

Our Story

Our founding team has been in the industry for many years and has often encountered the main bottleneck for customers: the supply chain for sourcing custom mechanical parts is very complex and slow to respond.

The characteristics of the traditional custom manufacturing supply chain are: fragmented, slow, inflexible, non-scalable, and rife with quality issues and delays. In addition, engineering and supply chain teams are often severely under-resourced and lack the channels and time to manage the complexity of the custom manufacturing supply chain; especially in the face of supply chain disruptions and changing global trade. All of these issues bring huge risks in the process of developing and launching new manufacturing products.

To solve this problem, Xtproto has established a supply chain system for custom manufacturing that combines the Internet and digitalization. We can seamlessly connect global branches and manufacturing plants, managed by experts in our global supply chain center. By working with Xtproto, engineering and supply chain teams can simplify the supply chain process of part customization and provide digital tools such as quick quotes, design for manufacturability feedback, and order management to help customers accelerate time to market, reduce supply chain risks, and achieve more goals with less investment.

Ready to get started?

From prototype to production, our team of engineers is ready to help you turn your ideas into reality.