Xtproto Solutions for the Automation Industry

Xtproto accelerates industrial automation through precision manufacturing and seamless procurement. From prototyping to mass production, we’re your one-stop partner.

A one-stop shop for your automation project needs

Automation products boost profits by increasing productivity, reducing costs, and enhancing safety, precision, and environmental practices. At every stage of your project, Xtproto supports your goals through custom part manufacturing, semi-standard adjustments, and parts procurement—all provided by a trusted partner.

A one-stop shop for your automation project needs

Fully customized components designed to precise specifications.

Semi-Standard Parts

Standard base models that can be customized to meet specific project needs.

Standard Parts

Ready-to-use components that meet standard specifications. Universal Parts.

Phase-Specific Automation Solutions

Our solutions align with each project phase (initial, mid-stage, and final), addressing specific challenges to ensure precision parts meet your specifications, quality, and budget.

Design and Procurement Support

In the early stages of automation projects, design ambiguity, unclear specifications, unpredictable costs, and supplier concerns can make controlling costs, schedules, and quality difficult.

Expert Support

- DFM Feedback and Optimization: Expert advice for efficient, manufacturable design improvements.

- Procurement List Planning: Expert guidance in selecting optimal standard components and coordinating bulk purchases.

- Accurate Lead Time Estimates: Reliable schedules updated in real time through our online platform.

- Comprehensive Cost Management: Get instant quotes and flexible pricing to validate designs early and control project costs from start to finish.

Design Optimization and Assembly Support

In the midst of an automation project, extended custom part lead times, inconsistent quality risks, unplanned design changes, volume procurement barriers, and insufficient supplier support can threaten schedules and budgets.

Expert Support

- Real-time Production Tracking: Monitor order status 24/7 via an online platform or dedicated support.

- Strict Quality Control System: Multi-step inspections ensure the highest quality; rapid response to any issues.

- Fast Design Change Support: Quickly update designs through optimized production schedules—without additional costs or delays.

Manufacturing Capabilities

- Precision On-Demand Manufacturing: High-performance automation components with ±0.01mm tolerances.

- Assembly Support: One-stop assembly guidance, pre-assembly options, and responsive after-sales assistance.

Quickly respond to urgent needs

In the final stages, gaps in procurement plan execution and unexpected part issues during installation can delay commissioning and impact delivery schedules.

Expert Support

- Precise Procurement Execution: Supports on-time procurement by tracking and quickly resolving issues.

- Quickly Replace Missing Parts: Rapidly source or manufacture parts within 1-3 days.

- Responsive Problem Handling: Rapid part analysis and redesign to ensure fit, reliability, and performance.

Automaton Parts Made Easier, Faster

Automation Parts Procurement

We Manufacture Precision Parts

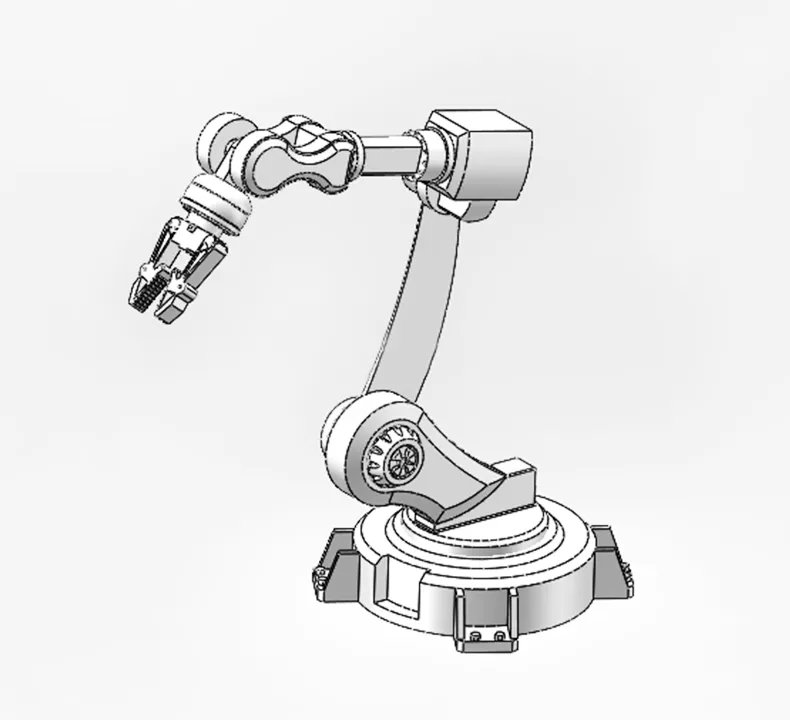

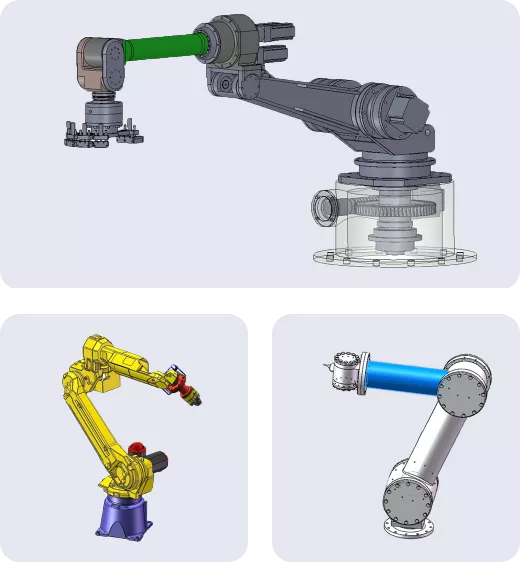

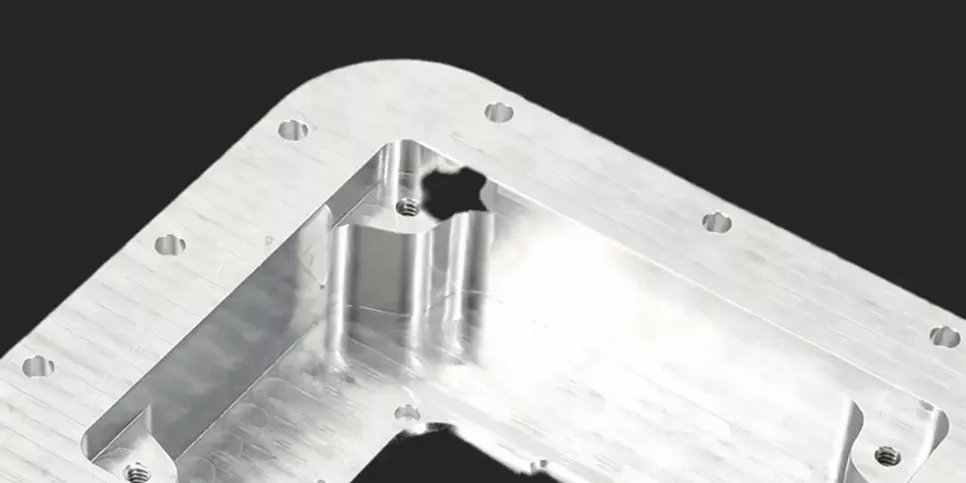

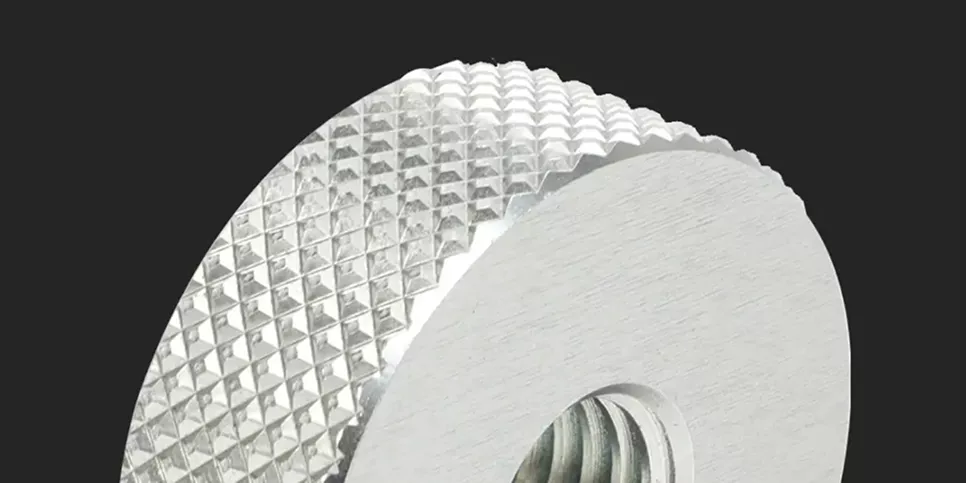

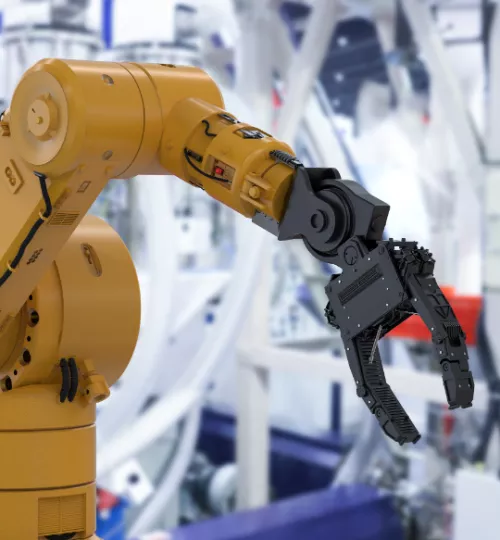

We specialize in high-precision automation components designed to achieve tight tolerances and superior performance. From EOAT (Electrobot Handling Tooling) and fixtures to gears, shafts, and structural frames, we achieve ±0.01mm accuracy in critical alignment, handling, and assembly processes.

With over 30 advanced five-axis CNC machining centers and a team of experienced engineers, we provide integrated design support and precision manufacturing services. Whether you’re using standard robots or collaborative robots, we can customize components to meet your automation needs.

From one-off prototypes to production runs, we’re committed to helping you build smarter, faster, and more reliable automation systems.

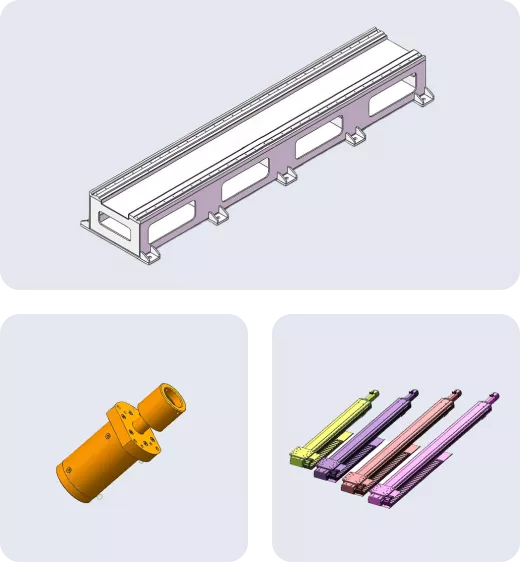

Customization Is Possible If Required

Semi-standard components offer ready-to-install convenience with optional adaptability. We provide a base model and can modify specifications (length, mounting method, material, etc.) to suit your project needs.

- Linear motion components

- Pneumatic components

- Transmission parts

- Hydraulic components

- Conveyor systems

- Frame & enclosure parts

- Fasteners

- Motors & drives

- Sensors

- Low-voltage electricals

- Aluminum profiles & accessories

We Source Standard Parts

We streamline automation projects by procuring standard components according to your BOMs for rapid integration. From guide shafts and sensor cams to valves and pneumatic clamps, we support:

Core Components:

Guide shafts, robot bodies, valves, linear guides, locating pins, fixtures, jigs, brackets, couplings, shafts, hinges, bushings, seals.

Support Systems:

Pneumatic/quick clamps, piping fittings, end-of-arm tools, pillars, bases, springs, magnetic products, nitrogen springs, dispensing accessories.

Support from an Expert Team

- Precision Manufacturing Expertise: High-precision machining and manufacturing, coupled with stringent quality control, deliver reliable, consistent parts to precise specifications every time.

- Dedicated Project Support Team: From design to delivery, our experts provide customized support, design analysis, procurement planning, and more for each project.

- Project Tracking: Upload files, get quotes, manage orders, and track production—all on our seamless, user-friendly platform.

Our Manufacturing Capabilities

CNC Machining

Injection Molding

Sheet Metal Fabrication

3D Printing

Extrusion

Die Casting

Vacuum Casting

Wire EDM

Materials

Find all the materials you need for product development across industries.

Metals

- Aluminium

- Copper

- Brass

- Bronze

- Steel

- Stainless Steel

- Magnesium

- Titanium

Plastics

- ABS

- PC

- PMMA

- POM

- PA

- PE

- PEEK

- HDPE

- HIPS

- LDPE

- PBT

- PP

- PAI

- PEI

- PET

- PPS

- PS

- PVC

- Teflon

- UPE

- Bakelite

- FR-4

Surface Finishing

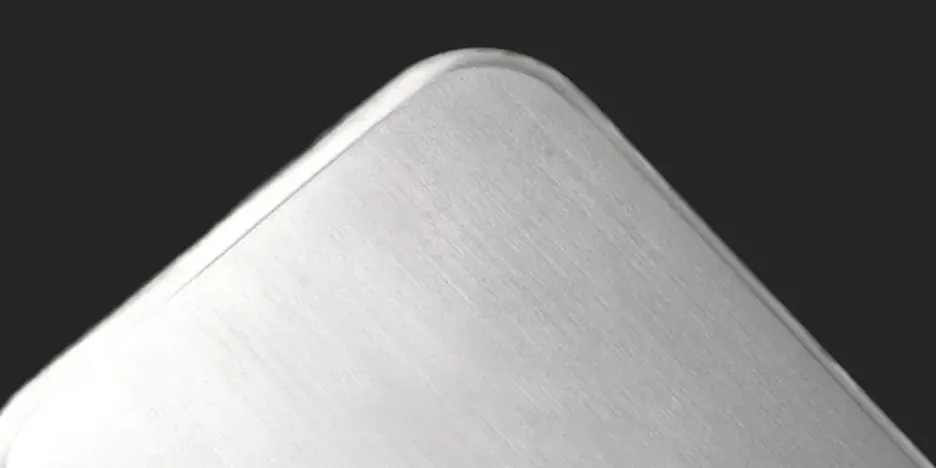

Customize your product’s look and durability with our surface finish options.

As Machined

Anodizing

Brushed Finish

Sand Blasting

Heat Treatment

Teflon Coating

Black Oxidize

Electroless Plating

Electroplating

Painting

Powder Coating

Electrophoresis

Tumbling

Alodine

Electropolish

Passivation

SPI Finish

Case Study

Precision Manufacturing & Assembly for 6-Axis Robots

Challange

A robotics company needed high-tolerance components for 6-axis robots (under 8 microns) and a streamlined assembly process to slash production time by 25%.

Solution

Xtproto delivered an end-to-end solution:

- Custom CNC-machined parts with 5-micron repeatability

- 6-axis robotic cells with auto-alignment for rapid assembly

- Real-time CMM checks during manufacturing and assembly

- AI workflow optimization to eliminate bottlenecks

Result

The integrated solution achieved 99.2% compliant parts with 7-micron assembly accuracy, cut total production time by 28%, and scaled to 5,000 units/month within 10 weeks — meeting both precision and speed targets without compromise.