CNC grinding is a precision manufacturing process that removes material from metal or plastic workpieces using a computer-controlled abrasive wheel. Unlike milling or turning, grinding achieves extremely tight tolerances and smooth surface finishes, making it ideal for complex shapes and high-precision components.

Grinding has a long history, dating back to when craftsmen used stones and simple tools to shape materials. During the 19th century, industrial grinding machines were developed, offering greater consistency and efficiency. The introduction of CNC (Computer Numerical Control) technology in the late 20th century revolutionized grinding, allowing automated, highly accurate production that meets the strict demands of industries such as aerospace, automotive, medical devices, and electronics.

Today, CNC grinding is essential for producing precision components from both metal and plastic. It ensures dimensional accuracy, consistent quality, and the ability to handle complex geometries that are difficult to achieve with traditional machining.

How CNC Grinding Works

CNC grinding is a precision machining process where a computer-controlled abrasive wheel removes material from a workpiece. Unlike milling or turning, grinding allows extremely tight tolerances and smooth surface finishes, even for complex shapes.

Preparing the Workpiece

Before grinding begins, the part is securely clamped to prevent movement. Proper alignment is essential for precision, as even minor shifts can affect the final dimensions.

Choosing and Dressing the Grinding Wheel

The type of abrasive wheel depends on the material and desired surface finish. Dressing the wheel restores its shape and sharpness, ensuring consistent material removal and accurate results.

CNC Programming and Operation

The CNC system controls the wheel’s movement, speed, and depth. Operators input the part geometry and machining parameters into the machine. The wheel gradually removes material along precise paths until the target shape and tolerance are achieved.

Types of Movements in Grinding

Different grinding operations require different wheel and workpiece motions:

- Surface grinding – the wheel moves across a flat surface.

- Cylindrical grinding – either the wheel or the part rotates to create round shapes.

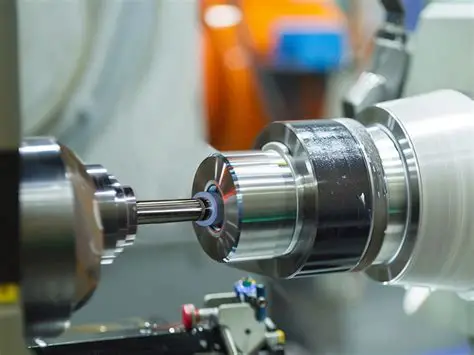

- Internal grinding – the wheel works inside a bore or cavity.

Automation and Precision Control

Modern CNC grinders include sensors and software that monitor temperature, vibration, and wheel wear. These systems help maintain consistent quality, prevent errors, and enable repeatable production for both prototypes and high-volume manufacturing.

Mastering Precision: Types of CNC Grinding & Industrial Applications

CNC grinding is not a one-size-fits-all process. The choice of grinding method dictates the achievable tolerance, surface integrity, and production efficiency. Below is a breakdown of the core CNC grinding technologies utilized at Xtproto.

Surface Grinding: The Foundation of Flatness

Surface grinding utilizes a high-speed rotating wheel to finish flat or contoured surfaces. It is the gold standard for achieving parallelism and flatness on square or rectangular stock.

Capabilities: Achieves mirror-like finishes ($Ra \le 0.2 \mu m$).

Applications:

- Tool & Die: Precision mold bases and plates.

- Aerospace: Turbine blade roots and structural components.

- Automotive: Cylinder heads and engine blocks.

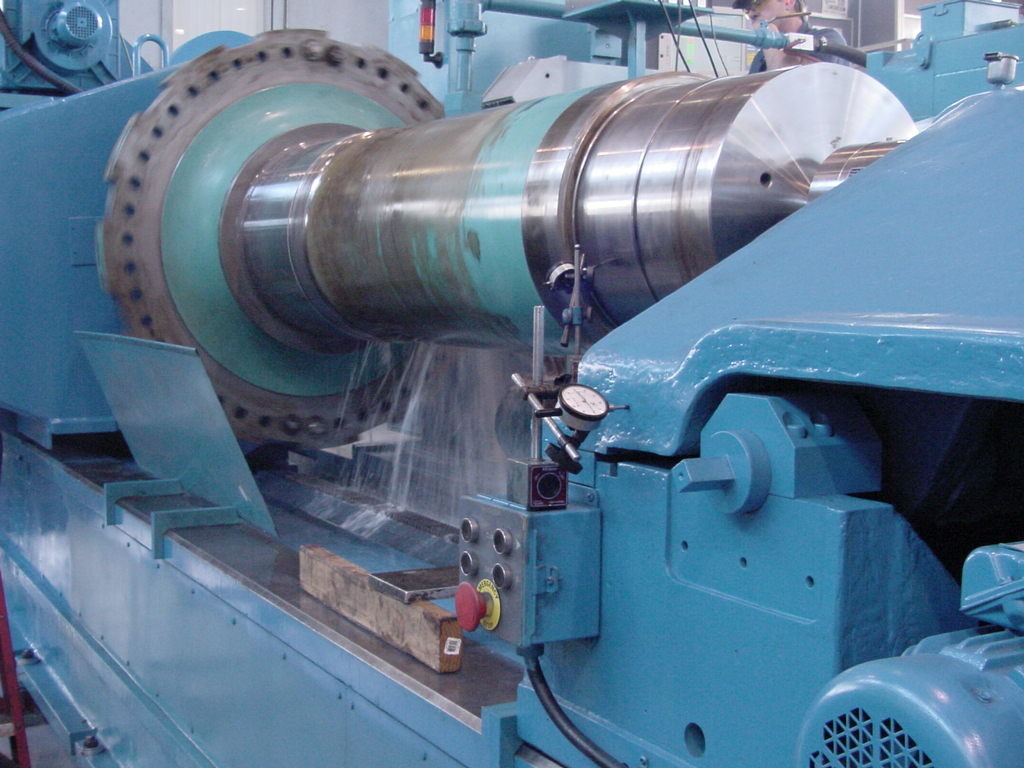

Cylindrical Grinding (OD Grinding)

This process involves rotating a workpiece around a central axis while the grinding wheel removes material from the exterior. It is essential for components that require perfect concentricity and run-out control.

Capabilities: Precision finishing of shafts, tapers, and stepped diameters.

Applications:

- Power Transmission: Transmission shafts and precision rotors.

- Medical: Orthopedic implants and surgical tool handles.

- Industrial: Hydraulic pistons and heavy-duty rollers.

Centerless Grinding: High-Volume Efficiency

Unlike cylindrical grinding, the workpiece is not held by centers. Instead, it is supported by a work-rest blade between a high-speed grinding wheel and a regulating wheel.

Key Advantage: Ideal for high-speed, continuous production of small-diameter parts.

Applications:

- Fasteners: High-tensile bolts, dowel pins, and rivets.

- Electronics: Micro-shafts for motors and actuators.

- Automotive: Valve stems and fuel injection needles.

Internal Grinding (ID Grinding)

Internal grinding focuses on the inner diameters (ID) of a part. It requires high-speed spindles capable of reaching deep into bores while maintaining extreme stiffness to prevent tool deflection.

Capabilities: Precision finishing of bores, bushings, and internal bearing races.

Applications:

- Aerospace: Landing gear cylinders and actuator bores.

- Manufacturing: Precision collets and tool holders.

- Fluids: High-pressure hydraulic valve sleeves.

Advanced & Specialized Grinding

When standard geometries won’t suffice, specialized grinding techniques provide the solution for complex profiles.

| Technique | Primary Benefit | Key Application |

| Gear Grinding | Eliminates heat-treat distortion in teeth. | High-performance racing gears. |

| Thread Grinding | Extreme lead accuracy for ball screws. | CNC machine tool lead screws. |

| Form Grinding | Replicates complex “negative” wheel shapes. | Turbine fir-tree roots & complex dies. |

| Creep Feed | High material removal in a single pass. | Heavy-duty aerospace alloys. |

Materials Suitable for CNC Grinding

| Material Category | Common Materials | Grinding Characteristics | Typical Applications |

| Carbon & Alloy Steel | Carbon steel, alloy steel | Excellent grindability, ideal for tight tolerances and finishing after heat treatment | Shafts, gears, machine components |

| Stainless Steel | 304, 316, 17-4PH | Tough material, requires controlled feeds and proper cooling | Medical parts, food-grade components, aerospace parts |

| Hardened Metals | Tool steel, hardened alloy steel | Suitable for grinding when conventional cutting is not possible | Bearings, dies, precision tooling |

| Aluminum & Non-Ferrous Metals | Aluminum, copper, brass | Requires special wheels to prevent loading and surface damage | Housings, electronic parts, lightweight components |

| Plastics & Polymers | PEEK, PTFE, Nylon, Delrin | Low grinding forces, used for dimensional accuracy and smooth finishes | Insulators, medical and electronic components |

| Ceramics & Specialty Materials | Technical ceramics, composites | Brittle materials, grinding enables precise shaping without cracking | Wear-resistant parts, high-performance applications |

Industries and Typical CNC Grinding Applications

CNC grinding is widely used across industries that demand high dimensional accuracy, consistent quality, and refined surface finishes. Rather than being limited to a single sector, grinding is applied wherever parts must meet strict tolerance and performance requirements.

Aerospace Industry

In aerospace manufacturing, CNC grinding is commonly used for components that operate under high stress and extreme conditions. Precision and repeatability are critical for both safety and performance.

Typical CNC grinding parts:

- Shafts and spindles

- Bearing components and races

- Precision housings

- Engine and turbine-related parts

Automotive Industry

The automotive industry relies on CNC grinding to achieve tight tolerances and high surface quality for both performance and durability. Grinding is often used as a finishing process after heat treatment.

Typical CNC grinding parts:

- Transmission shafts and gears

- Camshafts and crankshaft components

- Bearing seats and cylindrical pins

- Hydraulic and steering system parts

Medical and Healthcare Industry

Medical components require excellent surface finishes and precise dimensions to ensure reliability and safety. CNC grinding enables accurate machining of small and complex parts used in medical devices.

Typical CNC grinding parts:

- Surgical instrument components

- Implant-related parts

- Precision sleeves and bushings

- Small-diameter shafts and pins

Industrial Equipment and Machinery

CNC grinding is widely used in general industrial applications where parts must maintain accuracy over long operating cycles. Grinding ensures consistent dimensions and improved wear resistance.

Typical CNC grinding parts:

- Machine spindles and rollers

- Guide shafts and linear components

- Bushings and wear-resistant parts

- Tooling and die components

Electronics and Precision Engineering

For electronic and precision engineering applications, CNC grinding is used to achieve fine finishes and tight tolerances on small and delicate components.

Typical CNC grinding parts:

- Precision pins and connectors

- Motor shafts and micro-components

- Housings requiring smooth mating surfaces

Energy and Heavy Industry

In energy-related and heavy industrial applications, CNC grinding is applied to large or hardened components where accuracy and durability are essential.

Typical CNC grinding parts:

- Pump and valve components

- Large-diameter shafts

- Hardened wear parts and sleeves

Advantages and Disadvantages of CNC Grinding

| Aspect | Advantages | Disadvantages |

| Precision | Achieves extremely tight tolerances, often within microns | Requires precise setup and careful parameter control |

| Surface Finish | Produces smooth and consistent surface quality | Additional processes may be needed if surface damage occurs |

| Material Capability | Suitable for hardened metals and difficult materials | Not ideal for large material removal |

| Process Stability | High repeatability for consistent production | Sensitive to vibration and improper wheel selection |

| Complex Geometry | Capable of grinding internal features and complex profiles | Limited flexibility compared to some cutting processes |

| Production Efficiency | Ideal for finishing operations and precision parts | Slower cycle times compared to rough machining |

| Cost Consideration | Reduces rework by achieving final dimensions accurately | Higher machine, tooling, and operating costs |

When CNC Grinding Is the Right Choice

CNC grinding is best suited for parts that demand high precision, tight tolerances, smooth finishes, or machining after heat treatment. In many production workflows, grinding is used alongside milling or turning to achieve the final required specifications.

CNC Grinding Machines: Parts, Operation, and Cost

CNC grinding machines are designed to deliver high precision, stable performance, and consistent surface quality. Understanding their structure, operation, and cost factors helps engineers and buyers evaluate whether CNC grinding is suitable for a specific application.

Machine Parts Overview

A CNC grinding machine consists of several key components that work together to ensure accuracy and stability:

Grinding Wheel:The abrasive tool that removes material from the workpiece. Wheel type, grit size, and bonding material directly affect surface finish and accuracy.

Spindle System:Drives the grinding wheel at controlled speeds. High spindle rigidity and balance are critical for precision grinding.

Workholding System:Includes chucks, centers, fixtures, or magnetic tables that securely hold the part during machining.

CNC Control System:The brain of the machine, responsible for controlling movement, speed, feed rates, and grinding paths.

Wheel Dressing Unit:Restores the wheel’s shape and sharpness to maintain consistent grinding performance.

Coolant System:Manages heat generation, removes debris, and prevents thermal damage to the workpiece.

Operation Workflow

- Part Setup and Alignment:The workpiece is mounted and aligned to ensure accurate grinding.

- Wheel Selection and Dressing:An appropriate grinding wheel is selected and dressed for optimal performance.

- CNC Programming:Grinding paths, speeds, and depths are defined in the CNC system.

- Grinding Process:Material is removed gradually to reach the required dimensions and surface finish.

- Inspection and Adjustment:Finished parts are measured, and minor adjustments are made if necessary.

Price Range and Cost Factors

CNC grinding machines vary widely in cost depending on their configuration and capabilities.

Key cost factors include:

- Machine size and axis configuration

- Grinding type (surface, cylindrical, centerless, internal)

- Automation level and tooling options

- Brand, precision class, and control system

In addition to machine price, operating costs such as tooling, maintenance, energy consumption, and skilled labor should also be considered.

Machine Selection Tips

When selecting a CNC grinding machine, consider the following factors:

- Required tolerance and surface finish

- Part size, geometry, and material

- Production volume (prototype vs. batch production)

- Flexibility for future applications

Choosing the right machine ensures both efficiency and long-term manufacturing stability.

Operation Tips and Best Practices

To achieve optimal grinding results:

- Abrasive Matching: Select CBN for hardened steels and Aluminum Oxide for general alloys. Match grit size to your required $Ra$ finish.

- Precision Dressing: Dress wheels frequently to prevent “glazing.” Truing is mandatory to eliminate chatter and ensure concentricity.

- Thermal Control: Aim high-pressure coolant directly at the contact zone. Clean coolant is key—use filtration to avoid surface scratches.

- Vibration Management: Always dynamically balance the wheel assembly. Even micro-vibrations will ruin sub-micron tolerances.

- In-Process Inspection: Check the “First Article” for dimensions and surface roughness. Use data to adjust CNC wear offsets immediately.

Common Challenges and Solutions

| Challenge | Common Cause | Practical Solution |

| Surface burns | Excessive heat | Improve cooling and reduce feed rate |

| Dimensional inaccuracy | Improper setup or wheel wear | Re-align workpiece and dress wheel |

| Poor surface finish | Incorrect wheel selection | Adjust grit size or wheel material |

| Vibration or chatter | Low rigidity or imbalance | Improve fixturing and spindle balance |

FAQs

How Much Does CNC Grinding Cost?

The cost of CNC grinding depends on part complexity, material, tolerance, and production volume. Harder materials, tight tolerances, or complex geometries generally increase costs, while standard parts with moderate tolerances are more economical.

How Accurate is CNC Grinding?

CNC grinding can achieve extremely tight tolerances, often within a few microns. Accuracy depends on the machine quality, grinding wheel selection, setup, and process control, making it ideal for high-precision parts with smooth surfaces.

How Long Does CNC Grinding Typically Take?

Cycle time varies based on part size, geometry, material, and tolerance requirements. Small or simple parts are finished faster, while complex or hardened components require more time. Grinding is often used as a finishing operation after milling or turning.

How Much Does a CNC Grinding Machine Cost?

CNC grinding machines range widely in price depending on type (surface, cylindrical, centerless, internal), size, axis configuration, automation level, and precision class. Higher-precision machines cost more but provide greater consistency and repeatability.

What is the Difference Between CNC Grinding and CNC Milling?

CNC grinding uses an abrasive wheel to remove material, achieving high precision and smooth surface finishes. CNC milling uses cutting tools to remove material more quickly. Grinding is ideal for finishing, hardened materials, and tight tolerances, while milling is better for bulk material removal and rough shaping.