Robotic Automation and Artificial Intelligence

Xtproto provides custom robot component manufacturing services. From humanoid robots and medical robots to warehouse robots, Xtproto is your ideal partner to accelerate robot component development, helping you go from rapid prototyping to mass production. We offer speed, quality, and scale advantages, enabling you to bring your products to market faster and maintain a competitive edge.

Digitally Efficient Robot Manufacturing

Xtproto offers exceptional on-demand robot manufacturing services, helping you turn your robot part concepts into reality. Our strong manufacturing capabilities and advanced technology meet the unique needs of the robotics industry. We are committed to providing high-quality industrial-grade robot prototypes and parts to help you achieve your product development goals.

Our extensive manufacturing capabilities, from small-batch prototyping to large-scale production, can meet everything you need to build robots. Whether you are developing unique end effectors, custom grippers or tooling fixtures, or building entirely new robot systems with numerous custom components, our trusted network of manufacturers provides unlimited capacity to help you produce highly customized parts.

Unleash Your Potential with Agile Manufacturing

Scalable Production

Flexible manufacturing supports smooth transitions from prototyping to mass production while maintaining precision, speed, and consistency.

Seamless Integration

Advanced machining ensures precise tolerances, material compatibility, and flawless fit for robotic assemblies within automation workflows.

Regulatory Assurance

Manufacturing meets ISO, AS9100, RoHS, and REACH standards, ensuring safety, reliability, and compliance for robotics across industries.

Xtproto's Comprehensive Robotics Manufacturing Capabilities

Robotics plays an increasingly vital role in industry, handling repetitive and hazardous tasks, improving productivity, and streamlining material handling and logistics processes. They bring consistency, accuracy, and precision to virtually every industry. Xtproto is at the forefront of this transformation, collaborating with numerous leading companies to create today’s most advanced robotic solutions and envision the future. From assembly station and pick-and-place robots to loading and unloading and autonomous driving technologies for delivery vehicles, Xtproto provides engineering and manufacturing expertise and produces high-performance custom parts for all sectors of the robotics and automation market.

How Xtproto helps you meet your robot parts needs?

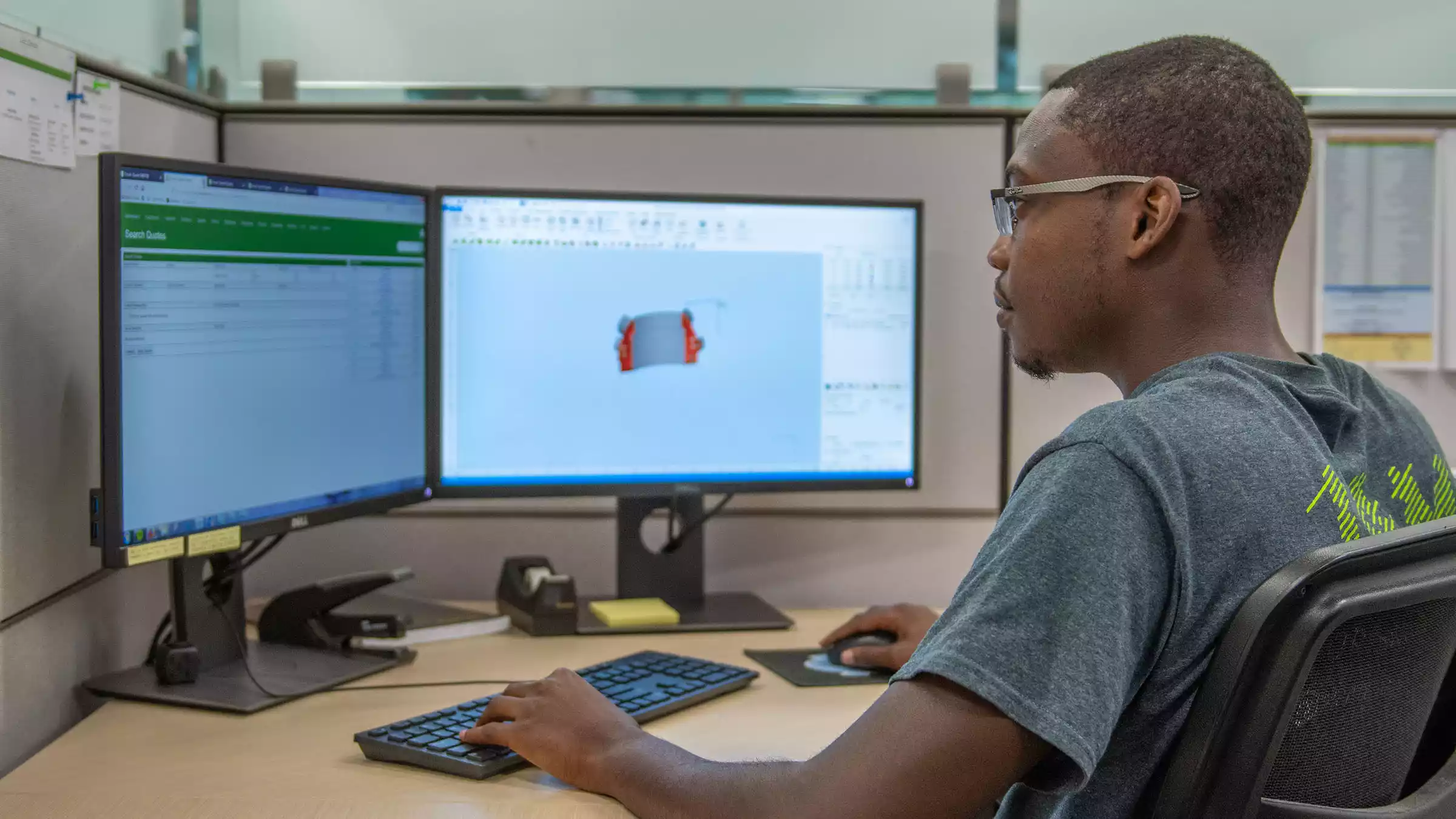

Your partnership with Xtproto begins with a hands-on, personalized service. You’ll communicate directly with an engineer who will work closely with you to deeply understand your requirements. For example, our meticulous Design for Manufacturing (DFM) process can help you identify and resolve potential design issues early in product development and provide improvement suggestions, thereby enhancing the manufacturability of your parts.

We will help you optimize part design, production processes, and material selection to achieve the best results at the best price. Our experienced engineers will assist you in efficiently moving your project from the prototyping stage to mass production. We focus on small-batch, highly customized parts, which is a perfect fit for this fast-paced, innovation-driven industry.

How do Robotics Companies Use Xtproto?

Rapid Prototyping

Take advantage of design for manufacturability (DFM) feedback in our instant quotes to make adjustments to part design before any manufacturing begins, then navigate quickly through early- and late-stage prototyping with ease.

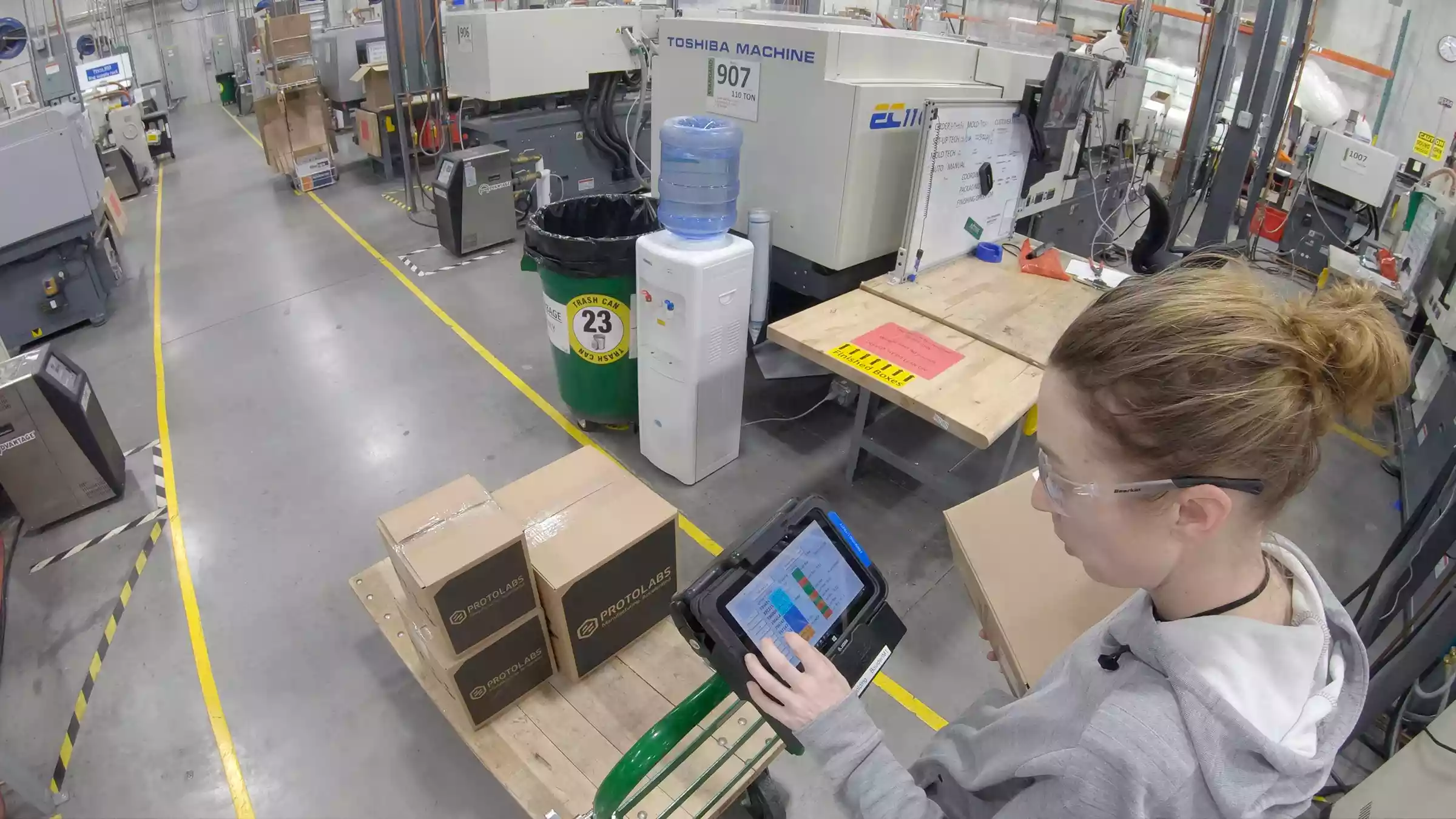

On-Demand Production

Whether it be custom parts at low volumes or repeatable parts at higher quantities, build agility into your supply chain by ordering quick-turn parts when needed.

Maintenance, Repair, and Operations (MRO)

Order custom production parts on demand for MRO applications to keep robotics equipment running without delay.

Quality Certifications & Traceability

Take advantage of our ISO 9001-certified manufacturing process for high-requirement parts.

Range of Materials

Choose from machined metals like aluminum, titanium, and stainless steel 17-4 PH along with plastics such as POM and elastomeric resins.

Our Manufacturing Services

Xtproto offers a wide range of materials for our clients to choose from, so they can create the perfect part. With traditional manufacturing methods like metalworking and plastic injection molding available, we have all your needs covered!

CNC Machining

Injection Molding

Sheet Metal Fabrication

3D Printing

Extrusion

Die Casting

Vacuum Casting

Wire EDM

Cutting-Edge Robot Prototyping: From Concept to Completion

Now you can easily customize low-cost robot parts. We are able to quickly print your parts using a variety of materials, including plastics, metals, and composites. Furthermore, we offer direct digital manufacturing services for large-volume custom parts. With Xtproto, you can quickly and easily order single parts or small batches. If your business is looking for customized solutions or needs disposable parts, Xtproto is the ideal choice. Thanks to 3D printing and additive manufacturing technologies, part manufacturing costs have been significantly reduced, making them more affordable than ever before.

Full Production Support Team

We have a team of manufacturing experts working behind the scenes to fulfill your production order—we manage the entire process and keep you updated along the way.

Account Manager

Applications Engineers

Logistics

Quality Control

Bring your humanoid robots, robotic arms, or underwater drones to life.

If you’re still in the early stages of product development, struggling to validate your ideas, excessively long lead times can quickly become impractical. Xtproto offers 3D printing and rapid prototyping services for a wide range of robotic applications, including drones, aerial robots equipped with cameras, active lighting, and even sensor components. We can help you create physical prototypes of your designs quickly and cost-effectively.

Custom Robotics Manufacturer for the Full Product Lifecycle

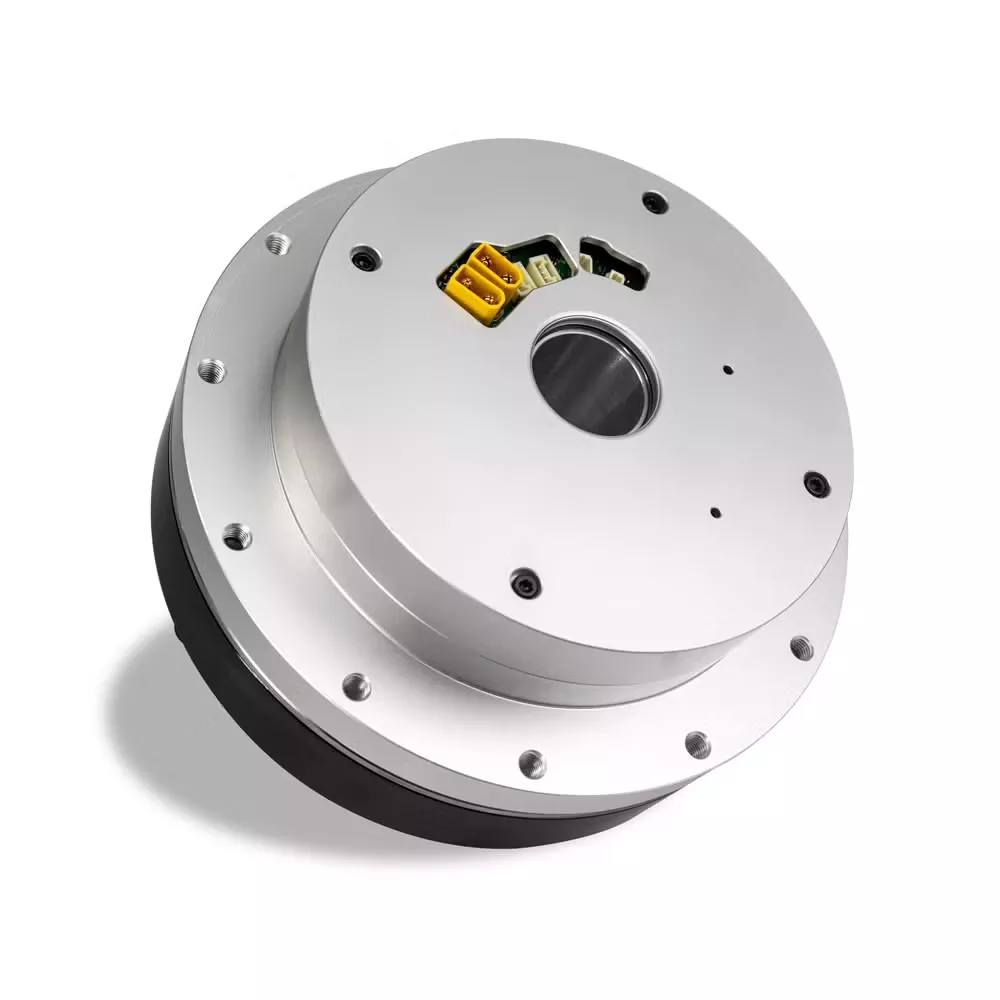

Leading robotics companies count on Xtproto for manufacturing parts and assemblies, such as:

- Humanoid: Chassis/frame, structural skeleton, joints & bearings, rotary joints & gears, and more

- Medical:Robotic surgical systems, actuators, prismatic joints, clean room capabilities, finishing & testing, compliance expertise, and more

- Industrial Automation: Robotic arm frames, end effectors, wheels/tracks/legs, chassis, and more

- Last-Mile Delivery: Wheels/tracks/legs, structural framing, chassis, enclosures, and more

- Warehouse: Wheels/tracks/legs, robotic arm frames, chassis, modular mounting systems, and more

Robotics manufacturing materials

We offer a huge range of material possibilities with all our manufacturing processes. Some common choices for robotics projects are listed below.

- Stainless Steel

- Aluminum

- PoM/Delrin

- Silicone

- Urethanes

Applicable Finishes For Robotics Industry

Xtproto offers wide variety high level surface finishes. We only list some of the common finishing options. There are more finish options for custom parts for Robotics Industry.

- As machined

- sanding & Polishing

- Sand, Bead Blasted

- Painted

- Powder coat

- Anodized

- E-Coating

- Nickel Plating

- Chromed

- Zinc Plating

Robotics Industry Solutions Provider

Xtproto is a leading robotics industry solutions provider, specializing in the design, development, and production of advanced robot components. We utilize the latest manufacturing technologies and proven processes to create customized solutions for our clients, including robotic grippers and other components critical to the robotics industry.

We deeply understand the robotics industry’s demands for precision, accuracy, and speed. The company employs advanced processes such as robot prototyping, 3D printing, CNC machining, and laser cutting to ensure products meet superior performance and quality standards. Whether you need customized military robots or drone production systems, we possess the expertise and resources to provide the best solutions. The Xtproto team is committed to providing exceptional customer service and support. In the rapidly evolving robotics industry, Xtproto prides itself on being at the forefront of innovation and technology.

Why Choose Xtproto?

- We possess comprehensive systems, processes, and technical expertise to deliver customized, small-batch parts tailored to your needs.

- We focus on new product innovation, keeping pace with your speed and agility.

- We understand that your parts, as part of a robotic or automation solution, must operate in high-performance environments.

- We can support every stage of your product development lifecycle—from early prototyping and validation to full-scale production.

- We have unparalleled manufacturing technology advantages. All our technology is developed in-house, not relying on third parties, enabling us to meet all your needs, including robotic additive manufacturing, injection molding, sheet metal fabrication, and precision CNC machining.

- We have extensive experience delivering high-quality parts to numerous robotics companies, military institutions, and other organizations serving this rapidly evolving, cutting-edge industry.

- We are problem-solving experts. Whether you have complex geometries, small-batch/multi-variety parts, or seemingly “impossible” projects, leave it to us. We will help you accomplish your tasks successfully.

The Future Development of the Robotics Industry

The robotics industry refers to the technological field involving the design, development, production, and application of robots. It encompasses multiple industries, including manufacturing, healthcare, automotive, aerospace, and military. The robotics industry utilizes various types of robots, including industrial robots, service robots, and collaborative robots, to automate tasks and improve productivity, efficiency, and safety in different fields.

The robotics industry chain is divided into three categories: upstream core component R&D and production, midstream fuselage manufacturing and system integration, and downstream applications in multiple industries. In recent years, robotics technology has developed rapidly. Advances in machine learning, artificial intelligence, and sensor technology have enabled robots to perform increasingly complex tasks. The robotics industry has a significant impact on the global economy. Furthermore, the growth of the robotics industry has created new employment opportunities in various fields such as robotics engineering, programming, and maintenance. The robotics industry has the potential to revolutionize many industries and transform the way we live and work by developing robots capable of performing tasks that were previously impossible.

Start Your Next Robotics Project Today

If you have drawings, including dimensions, customization requirements, etc., please send the drawings directly to us.Looking forward to cooperating with you!