Manufacturing Certification

Our network of rigorously audited digital manufacturers and ISO 9001-certified quality management systems ensures your parts consistently meet industry-specific certifications. Our network certifies to the following standards: AS9100-D, ISO 9001:2015, ISO 13485, ISO 14001, and ISO TS16949.

Xtproto is committed to quality and safety

Xtproto understands that a rigorous quality management system (QMS) and accurate, comprehensive documentation are crucial to providing high-quality, compliant parts to customers. Xtproto holds multiple certifications across its global manufacturing network to ensure all parts meet stringent specifications and requirements. Xtproto’s extensive certifications include ISO 9001:2015, ISO 9001:2015 Design Certification, ISO 13485:2016, AS9100:2016, and NIST 800-171.

ISO 9001:2015

ISO 9001:2015 is an international standard that specifies requirements for a quality management system (QMS). Organizations that adopt this standard must demonstrate their ability to provide products and services that consistently meet customer and regulatory requirements. The seven principles of ISO 9001:2015 include customer focus, leadership, employee engagement, a process approach, improvement, evidence-based decision-making, and relationship management.

AS9100:2016

AS9100:2016 certification is an internationally recognized quality management system (QMS) for the aviation, space, and defense (ASD) sector. This QMS revision is based on the ISO 9001:2015 quality system requirements, which set the standard for companies providing design, development, production, installation, and/or services in the ASD industry.

ISO 13485:2016

ISO 13485:2016 defines the quality management system (QMS) requirements for companies providing medical devices and related services to ensure that customer needs and applicable regulatory requirements are consistently met. Organizations that meet the standard can participate in any stage of the product lifecycle, including the design and development, production, storage and distribution, installation, and/or maintenance (e.g., technical support) of medical devices. Suppliers or external vendors providing product materials may also be required to comply with ISO 13485:2016. While ISO 13485:2016 outlines requirements for medical devices, they also apply to all related services provided by the organization.

Why choose Xtproto?

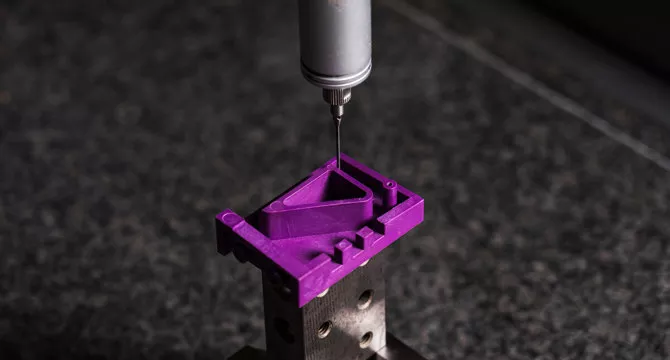

You can trust Xtproto. As a technologically advanced manufacturer, Xtproto maintains a comprehensive quality policy that aligns with Fathom’s commitment. Xtproto uniquely integrates industrial 3D printing and additive manufacturing with traditional manufacturing, delivering a differentiated customer experience focused on speed, urgency, and agility.

Xtproto’s quality policy sets a clear framework for overall quality goals. These goals outline our commitment to customer satisfaction through Xtproto’s comprehensive capabilities, expertise, and continuous improvement initiatives.

Xtproto’s experts are dedicated to understanding and anticipating customer needs to meet project requirements and exceed expectations. Speak with an Xtproto expert today.