Xtproto's End-to-End NPI Solution

Xtproto simplifies the process of launching new products from concept to market.

Common Challenges of New Product Launch

Bringing a new product to market is a complex process, and many teams face key obstacles at different stages. Here are some common pain points.

Design-Manufacturability Gap

Aesthetic concepts don't always translate well to production, leading to costly revisions.

Unfamiliarity with Materials and Processes

Designers may lack expertise in unconventional materials and advanced manufacturing techniques.

Suboptimal Manufacturing Strategies

Most suppliers struggle to adapt to evolving validation requirements while balancing cost and performance.

Fragmented Supply Chain

Sourcing disparate parts from multiple suppliers often leads to inconsistent quality and schedule delays.

Late Design Flaws

When problems arise after all parts have been delivered, assembly bottlenecks can occur, slowing down iterations.

Providing seamless solutions for every product development milestone

From initial idea to final packaging, Xtproto supports you.

Project Initiation

We support your NPI journey through strategic project planning and risk management.

- Manufacturing Feasibility Review: Analyzes the manufacturability of your product design, including considerations of product design, mold design, assembly, and other related aspects.

- Cost Forecasting: Provides preliminary cost estimates based on product design and manufacturing processes, helping designers incorporate cost considerations during the design phase.

- Risk Assessment: Proactively identifies potential risks that may arise during the manufacturing process and proposes corresponding mitigation measures.

Ideation and Concept

We transform early visions into manufacturable realities with expert guidance.

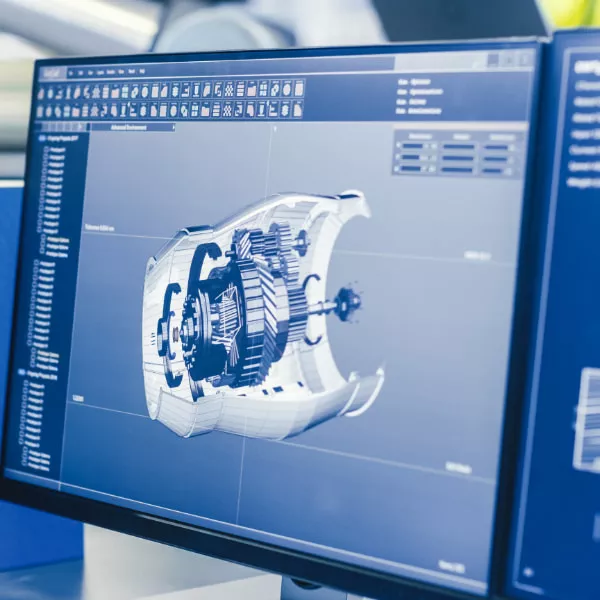

- Design Optimization: Recommend improvements to product form, cost, manufacturing feasibility, and lifecycle management (assembly/maintenance/transportation). Optimize surface details to enhance aesthetics and structural resilience.

- Material and Process Guidance: Guide material selection based on cost/performance metrics and recommend alternatives for overdesigned components. Ensure manufacturing methods align with design complexity and precision requirements.

- DFM Analysis: Verify internal component architecture, assembly logic, and mechanical system compliance. Ensure designs meet functional specifications while maintaining manufacturability.

- Cost Estimation: Generate hierarchical budget forecasts through analysis of historical manufacturing data and quantify the financial impact of decisions with scenario-based variance reporting.

EVT and DVT Prototyping

We validate materials, optimize design-process pairings, and streamline assembly through stress testing protocols to ensure manufacturability and regulatory compliance.

Manufacturing Recommendations

- Material Selection Consulting: We select materials based on your testing needs, validate their performance, and provide alternatives when needed.

- Design-Process Synchronization: We align your design with optimal production methods to avoid issues and improve product quality.

- Process Optimization: We select the manufacturing process appropriate for your design, analyze quality and cost impacts, and recommend improvements.

Assembly and Testing

- Assembly Process Engineering: We recommend efficient assembly methods and sequences to save time and cost.

- Quality Verification Systems: We develop step-by-step testing plans for functionality, performance, and reliability to ensure your product operates flawlessly.

Low Volume Production

We verify the manufacturability and consistency of production, ensuring that processes, equipment, and quality control systems reliably produce compliant products.

- Production process optimization recommendations: Based on the PVT testing results, we further optimize the production process to improve production efficiency, reduce costs, and ensure consistent product quality.

- Establish a quality control system: This includes developing detailed quality control plans, inspection standards, and methods.

- Raw material procurement and management: We assist in developing raw material procurement plans to ensure timely supply and cost control. We also conduct quality inspections of raw materials to ensure they meet production requirements.

- Manufacturing services: Verification of small-batch production.

Mass Production

We streamline our supply chain, improve accuracy through intelligent inspections, and reduce costs while maintaining tight delivery times, resulting in quality you can trust.

- Supply Chain Integration: We integrate our own in-house factories with numerous manufacturing facilities and various process-related plants.

- Quality Control and Inspection: We implement rigorous inspection measures covering raw materials, process steps, and finished products, equipped with intelligent testing equipment and online systems to improve efficiency and accuracy.

- Technical Support and Solution Provision: Our project team provides technical solutions to help resolve production issues, optimize processes and quality control, and ensure product stability and consistency.

- Cost Control and Delivery Management: We assist project teams with cost management and delivery schedule management, providing estimation and evaluation services to ensure project efficiency and progress.

Assembly

We precisely assemble components, calibrate for optimal performance, and conduct rigorous inspections to ensure each product meets stringent quality standards.

- Assembly: Components are assembled according to drawings and workmanship specifications, ensuring dimensional accuracy and assembly quality.

- Adjustment and Calibration: After assembly, parts are adjusted and product performance is verified to ensure compliance with design specifications.

- Inspection: Appearance, performance, and functionality are rigorously inspected to ensure compliance with quality standards.

Packaging

We design shelf-ready packaging that combines eye-catching aesthetics with rugged protection, meticulously crafted to your brand specifications.

- Packaging Design: We select materials, design structure, graphics, and text based on product characteristics and customer requirements, ensuring safety while enhancing aesthetics.

- Packaging Manufacturing: We provide custom, precision-manufactured packaging containers such as cartons, paper bags, plastic bags, and metal cans.

Why choose our NPI solutions?

Our Manufacturing Capabilities

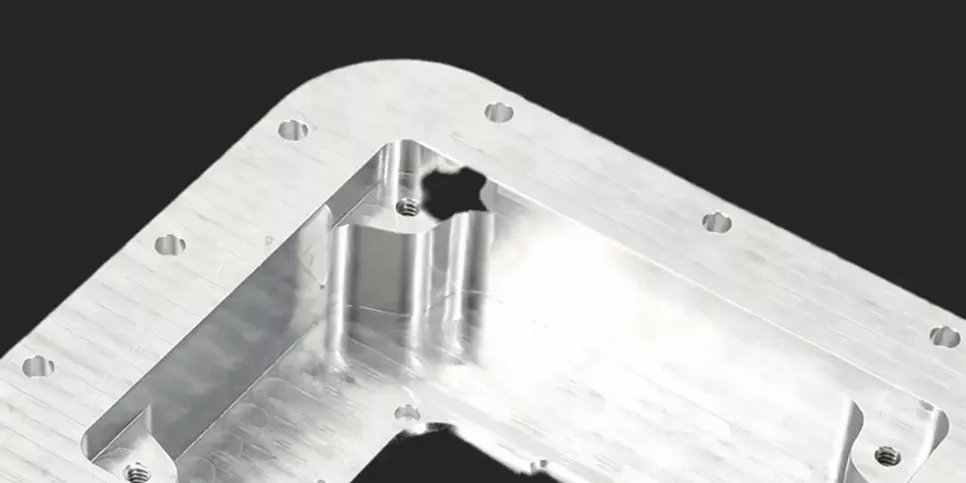

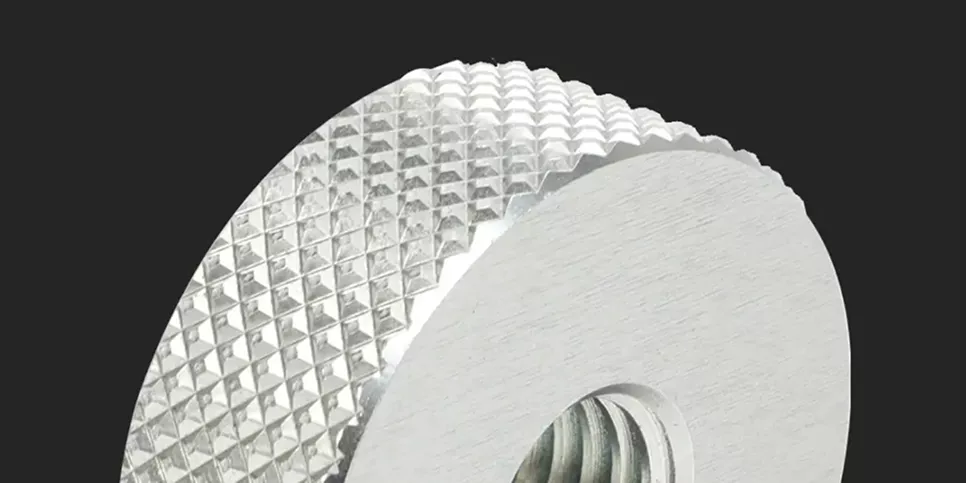

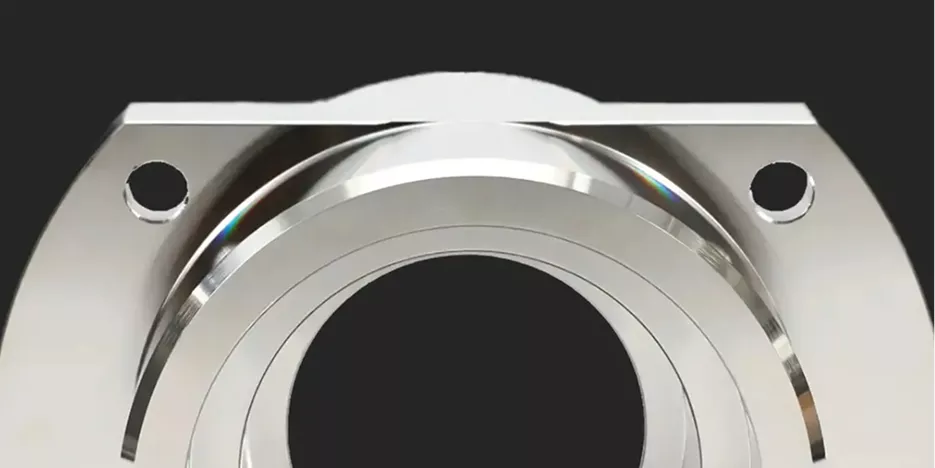

CNC Machining

Injection Molding

Sheet Metal Fabrication

3D Printing

Extrusion

Die Casting

Vacuum Casting

Wire EDM

Materials

Find all the materials you need for product development across industries.

Metals

- Aluminium

- Copper

- Brass

- Bronze

- Steel

- Stainless Steel

- Magnesium

- Titanium

Plastics

- ABS

- PC

- PMMA

- POM

- PA

- PE

- PEEK

- HDPE

- HIPS

- LDPE

- PBT

- PP

- PAI

- PEI

- PET

- PPS

- PS

- PVC

- Teflon

- UPE

- Bakelite

- FR-4

Surface Finishing

Customize your product’s look and durability with our surface finish options.

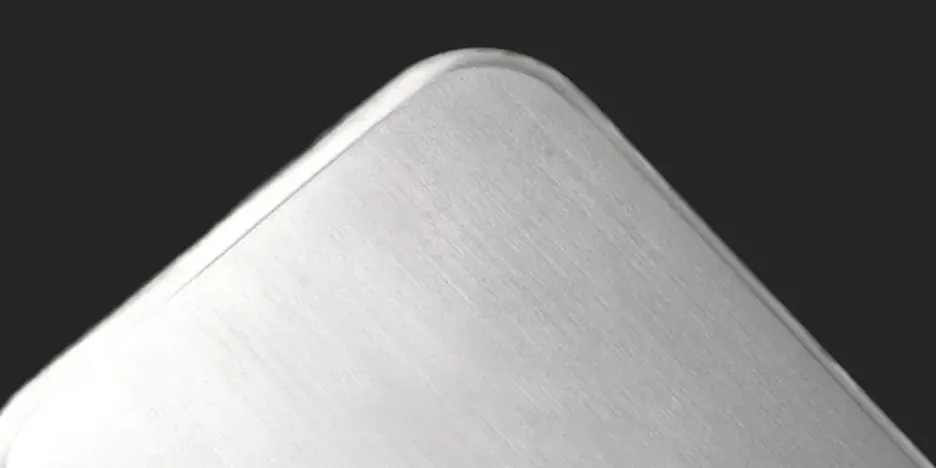

As Machined

Anodizing

Brushed Finish

Sand Blasting

Heat Treatment

Teflon Coating

Black Oxidize

Electroless Plating

Electroplating

Painting

Powder Coating

Electrophoresis

Tumbling

Alodine

Electropolish

Passivation

SPI Finish

Expanding Manufacturing Network Based in China

Xtproto’s China-based factories and vetted partners provide fast, scalable production of metal and plastic parts, ensuring NPI reliability and zero delays.

1000+

Machines Set

0.01

Tight Tolerance

1 Day

Fast Lead Time

Quality Assurance at Every NPI Stage

Xtproto prioritizes quality, employing CMMs, XRF analyzers, and precision tools for rigorous testing before, during, and after production. Our ISO-certified team, backed by 20 years of proven prototyping and manufacturing excellence, provides detailed reports on functionality, conformity, and dimensions.

- Over 30 testing devices

- 10 coordinate measuring machines

- Over 40 quality engineers

Ready to Develop Your New Product?

We are the world’s fastest digital manufacturing provider, delivering rapid prototyping and on-demand production parts. Our fast quoting and manufacturing network enable us to produce commercial-grade plastic, metal, and liquid silicone rubber parts within days. The result? We are your manufacturing partner, helping you accelerate time to market and strategically manage demand fluctuations throughout the product lifecycle.