Quality Assurance

Learn how we maintain quality processes with our global network of manufacturing partners. Xtproto’s team of engineers has developed a process to ensure that every custom part you order meets the highest manufacturing standards. We perform dimensional and visual inspections on every order during and after production to ensure your custom part is delivered on time and to your exacting specifications. This is a testament to our high standards.

Our Quality Control Steps

Xtproto is equipped with advanced in-house measuring and testing equipment. We maintain strict quality control throughout the entire production process to ensure that each project meets your requirements. Our quality assurance begins with incoming material inspection, followed by first-article inspection, in-process inspection, and final inspection and testing, with reports and certifications provided before shipment.

1. Material and Design Verification

Before production, our engineering team will conduct a technical review of your drawings (3D and 2D) to evaluate material selection, geometry, and process feasibility. We can also provide material certification upon request.

2. First Article Inspection (FAI)

Before mass production, we produce and inspect the first article to ensure it fully conforms to the design and tolerance requirements. A detailed inspection report will be submitted to the customer for confirmation.

3. In-Process Quality Control

Throughout the manufacturing process, Xtproto adheres to ISO 9001:2015 standards and performs regular inspections using precision measuring tools. This helps identify and correct deviations in real time, ensuring consistent part quality.

4. Final Inspection and Documentation

Each component undergoes final inspection for dimensions, surface finish, and appearance. We provide a complete inspection report and quality documentation (e.g., RoHS compliance) before secure packaging and shipping.

Quality Documentation

Our quality management team monitors the manufacturing of your parts to ensure they meet our quality standards and your project needs, and provides certifications and reports upon request.

Certificate of Conformance

Availability: CNC machining, injection molding, sheet metal fabrication

Material Test Report

Availability: CNC machining (metals)

CMM Inspection Report

Availability: CNC machining

REACH

Availability: CNC machining, sheet metal fabrication

Material Certificate

Availability: CNC machining, sheet metal fabrication

First Article Inspection (FAI)

Availability: CNC machining

Dimensional Inspection Report

Availability: CNC machining, 3D printing, sheet metal fabrication

RoHS

Availability: CNC machining, injection molding, sheet metal fabrication

Key Quality Control Equipment

Our quality control department uses advanced inspection tools, including height gauges, profile projectors, coordinate measuring machines, and Olympus metal testers, to meticulously inspect every component. This helps us provide high-quality, high-precision prototypes and precision-machined parts for a wide range of industries.

X-ray Material Testing Machine

Sourcing materials from suppliers without certification is extremely risky. Even with certification, you might end up receiving the wrong material. With an X-ray material tester, we can identify various metals in just 30 seconds, ensuring the correct material is used.

Imagine using the wrong material. A customer won’t be able to properly test their design. This could result in significant losses during mass production. In some industries, testing a prototype with the wrong material is extremely risky. In the worst-case scenario, you’ll have to remanufacture the part, even if delivery times are compromised. Thanks to the tester, all these issues are resolved.

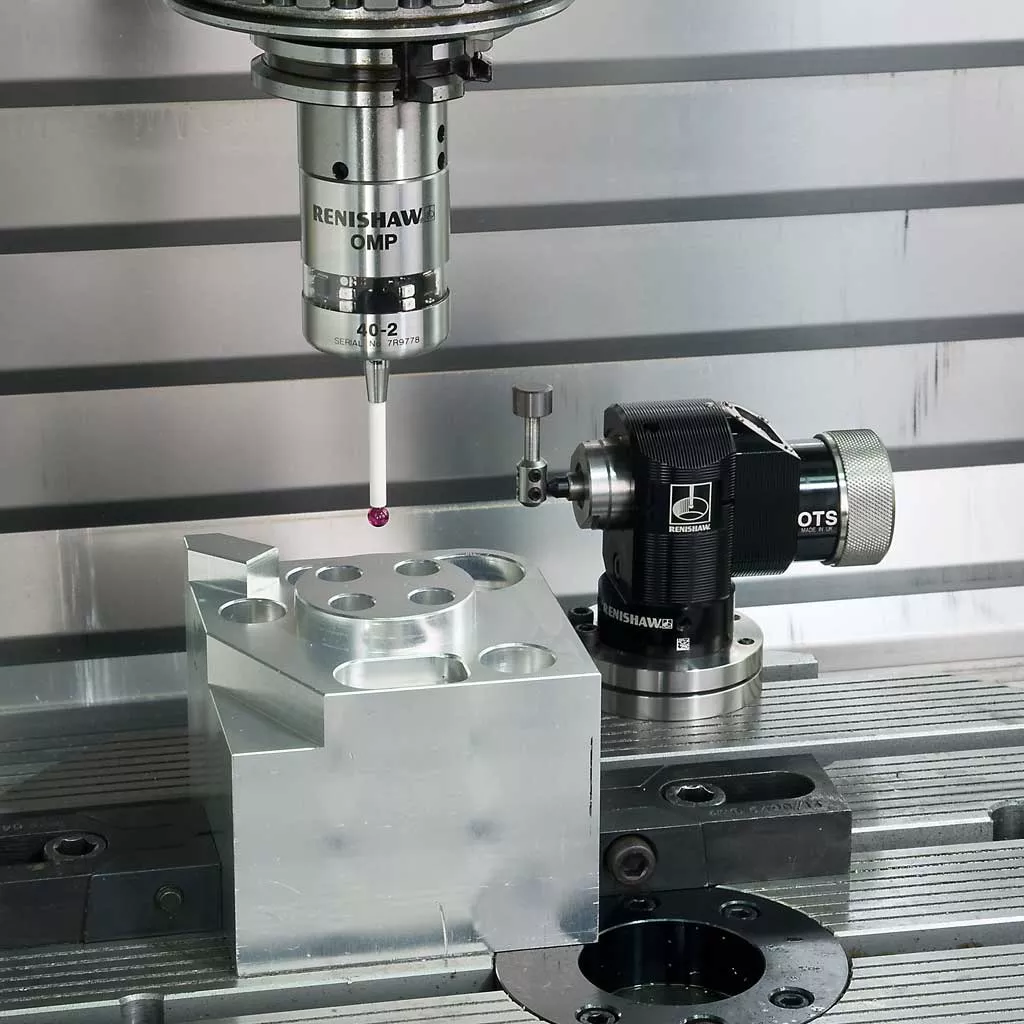

In-Machine Inspection System

Essentially, this system helps locate the material block. It’s faster and more accurate than manual operation! This is a huge advantage, especially when performing post-processing on die-cast parts or extruded profiles. As we all know, they can be inconsistent. Deformation is also a problem. With this system, you can manually inspect parts or pre-set inspection points. The system will automatically adjust the cutting path based on the inspection results. Identifying problems early can help us avoid further action, saving costs and time.

Projector

It can measure points, lines, circles, arcs, ellipses, and rectangles. It offers multi-point positioning, combined measurement, center construction, intersection construction, midpoint construction, line construction, and circle construction. It features a variety of data processing, display, input, and output functions. Measurement data can be directly exported to Word, Excel, and AutoCAD for statistical analysis. The workpiece alignment function is particularly useful.

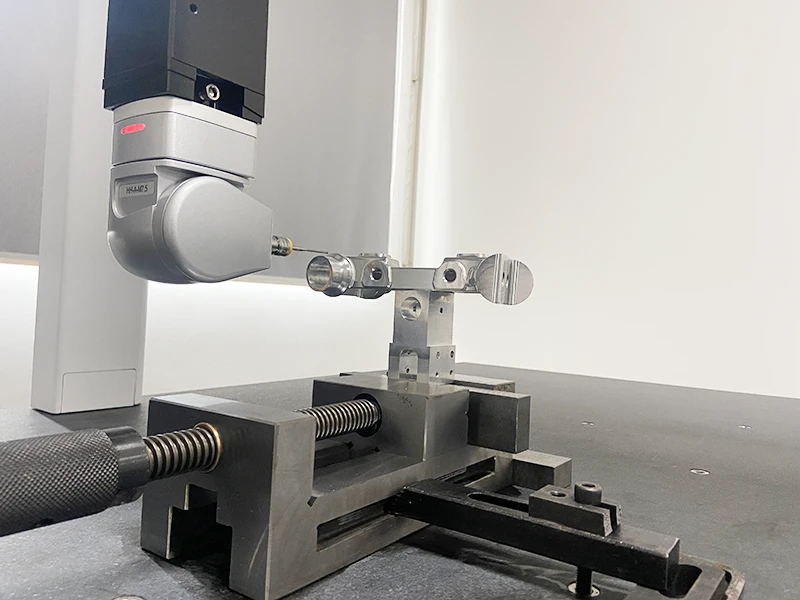

Coordinate Measuring Machine

The most basic definition of a coordinate is a point, a single fixed position in three-dimensional space. A series of points can be used to define the parameters of complex shapes. Therefore, a coordinate measuring machine (CMM) is any device that can acquire this set of points on a given object and measure it with acceptable accuracy and repeatability.

ISO 9001:2015 Certification

Xtproto’s in-house facility is proud to be ISO 9001:2015 certified. Our entire workflow, from sourcing to final inspection, adheres to strict standards to ensure consistent quality throughout the production process, full traceability and high customer satisfaction.

Your trusted partner for precision custom parts

Global quality, affordable pricing, and fast delivery