3D Printing

On-demand 3D printing for rapid prototyping and production in as fast as 1 day. Get an instant 3D printing quote with DFAM analysis today.

High-Quality 3D Printing Services

Get commercial-quality rapid prototyping and production parts from the experts in the additive manufacturing industry. XTPROTO sets the standard for cutting-edge, high-quality 3D printing services to meet the needs of the professional and commercial sectors. Our team specializes in aerospace and defense applications and is ready to tackle the most stringent regulations.

Whether you need precision prototypes or production-grade components and materials, we provide on-demand solutions and technical support to ensure your project stays ahead of the curve.

Our state-of-the-art equipment includes commercial and industrial 3D printers for a variety of technologies, including Stratasys F900, Neo 800, J850 Pro, and more. With XTPROTO, you can enter the forefront of additive manufacturing, ensuring that your projects in the aerospace and defense sectors benefit from precision, reliability, and innovation.

As your trusted partner, XTPROTO is the first choice for high-precision custom 3D printed parts designed for professional and commercial use. Upload your CAD file to get a custom quote and delivery time, streamlining the process for your convenience.

Why Choose XTPROTO?

XTPROTO is committed to providing excellent customer service and high-quality products. We have an excellent service team that can provide fast turnaround times and quality products to meet your specifications.

We provide CAD file design services and reverse engineering services. Whether you need to replicate an existing part or want to create something completely new, we are your best choice because our professionals have many years of experience in this industry.

Whatever your business is, we have the expertise to help you with your project management needs. Our team has extensive experience in functional prototypes and supporting materials to provide excellent services. With the help of our material characterization experts, we can quickly produce parts using injection molding, all at an affordable price. We are committed to providing you with high-quality 3D printing services. We provide fast turnaround times for your 3D prints and scans at very reasonable prices.

Our 3D Printing Capabilities

Our online 3D printing service enables you to 3D print custom parts on demand. We offer a variety of 3D printing technologies to transform your 3D files into plastic, metal, and elastomeric parts. With over 120 3D printers, we have unmatched capacity to reliably deliver parts within days. In addition to a wide selection of materials, we offer a variety of post-processing options to improve appearance or enhance mechanical properties.

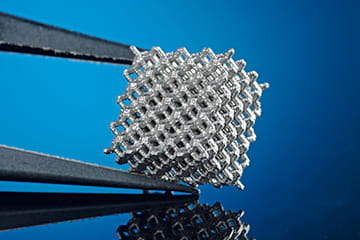

Metal 3D Printing

Direct Metal Laser Sintering (DMLS)

Stereolithography (SLA)

Selective Laser Sintering (SLS)

Multi Jet Fusion (MJF)

PolyJet

Carbon DLS

SLM

Fused DepositionModeling (FDM)

Metal Binder Jetting

Digital Light Processing (DLP)

3D Printing General Tolerances

- Part Size: XTPROTO can accommodate 3D printing up to 24″ x 36″ x 36″ without the need to split and bond parts.

- Minimum Feature Size: 0.030″ – 0.060″ is typical.

- Minimum Wall Thickness: 0.020″ – 0.060″ is typical.

- Clearance Between Features: At least 0.030″

3D Printing Materials

Our material selection includes plastic and metal options such as ABS, PA (Nylon), Aluminum, and Stainless Steel for a variety of industrial custom 3D printing projects. If you have unique material requirements, simply indicate when contacting us. We are committed to sourcing the materials you need.

Metal

- Aluminum

- Stainless Steel (17-4,316L)

- Titanium

- Inconel

- Cobalt Chrome

- Copper

Plastic

- ABS

- Polycarbonate

- Polypropylene

- Silicone

- Nylons

- Polypropylene

- TPU

- Elastomer (30A to 95A)

In-house Post-Processing

The R&D department has a wide range of tools and machines to remove support material from 3D printed parts. We use soluble support materials that allow for the creation of complex geometries.

We can also handle any 3D print post-processing including sanding, polishing, clear coating, marine epoxy coating (for waterproofing FDM), and adding thermoset inserts. For large printed parts or more specific post-processing techniques, we have an in-house shop to meet your needs.

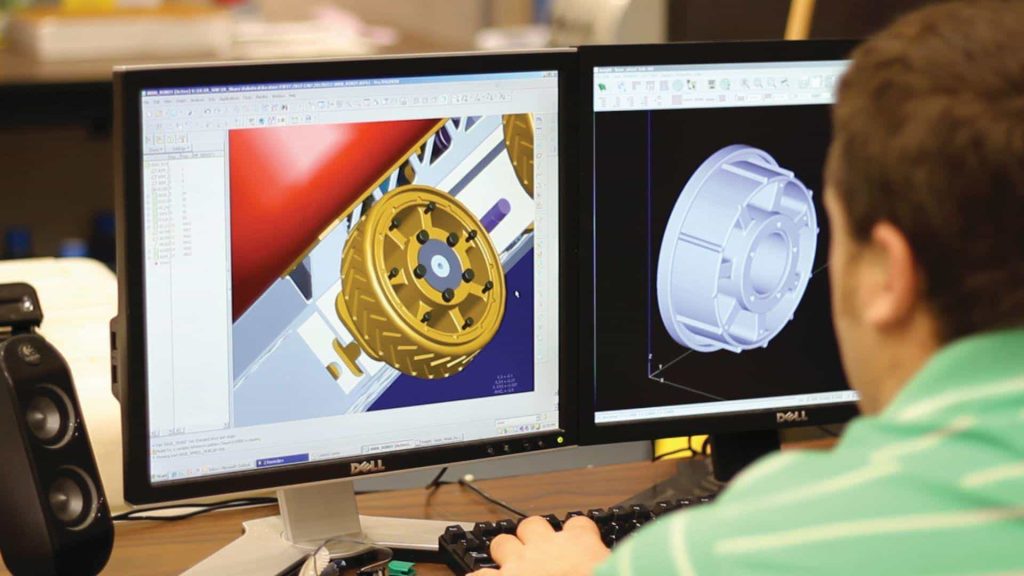

Mechanical CAD Design and Drafting Services

If you have a prototype or an idea but don’t have a 3D file, we can provide CAD design for your project using our Solidworks CAD software. For larger, more complex projects or organic shapes that require specialized CAD software, we are capable of outsourcing CAD services. Once you have the file, we can provide a quote and print your parts

From Prototyping to Production

Taking your next design from early-stage testing to full production has never been so easy.

XTPROTO’s simplified sourcing approach takes the work out of buying your prototype, models, and production parts. Let us be your one source of success!

3D Printing

Vacuum Casting

Injection Molding

What is 3D Printing?

3D printing is a term used to describe a number of additive manufacturing technologies that produce parts one layer at a time from a 3D digital model. Some 3D printing machines will extrude a filament to create a parts, while others use lasers to sinter or cure raw materials like metal or plastic powders and liquid resins. There are a variety of 3D printing technologies that differ in terms of materials, surface finish quality, cost, and quantity to name a few.

Advantages of 3D Printing

3D printing offers numerous advantages over traditional manufacturing methods.

- Customization: Easily create custom 3D printed items to meet specific needs without additional cost or complexity. Ideal for personalized items and bespoke solutions.

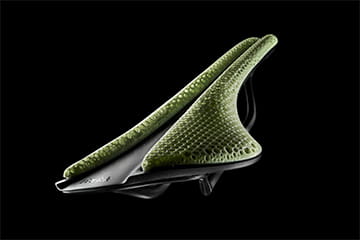

- Complex Geometries: Produce intricate designs and complex structures that are impossible with traditional manufacturing methods, enabling innovative and advanced product features.

- Reduced Waste: Additive manufacturing uses only the material needed, significantly reducing waste compared to subtractive manufacturing techniques.

- Rapid Prototyping: Quickly create prototypes to test form, fit, and function, accelerating the design and development process.

- Cost-Effective for Small Runs: Economically viable for low-volume production runs, eliminating the need for expensive tooling and molds.

- Speed to Market: Shorten production lead times, allowing faster iteration and quicker market introduction of products.

How XTPROTO's 3D printing services can help you

For agencies

We’ve helped agencies create custom 3d printed trophies, custom 3d printed props and other custom objects within time and budget.

For artists

With our industrial 3d printers, we can create 3d printed sculptures with smooth surface finish — making it perfect for silicon molds or adding a different finishing such as metal plating or painting.

For makers

We’ve helped engineers and product makers turn their ideas into reality — from rapid prototyping to manufacturing end products.

Ready to start making custom 3D printed parts?

XTPROTO offers a comprehensive range of additive manufacturing services to meet a variety of application needs. Whether you need a single prototype for rapid product development or a complex and durable part for mass production, our online 3D printing services can help you manufacture components quickly and more cost-effectively. This can speed up your innovation cycle, allowing you to focus on creating breakthrough products.