Custom Assembly Services

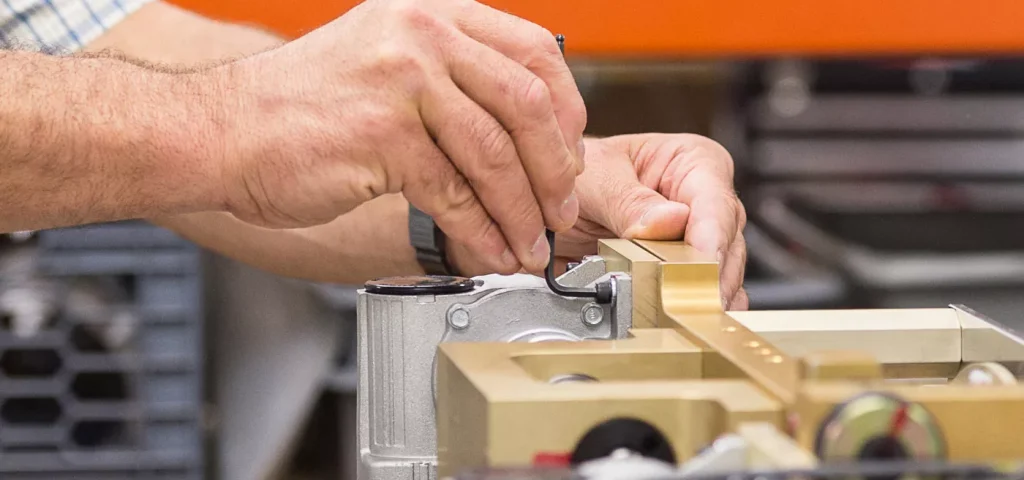

Our commitment to delivering comprehensive solutions extends to our Custom CNC Parts Assembly Service. Beyond precision machining, we offer a tailored assembly service that ensures the seamless integration of CNC parts into complex assemblies.Bringing your manufactured parts together! Our custom assembly services ensures quality, saves time, and meets unique project specifications.

Premium Assembly Services from Xtproto

At Xtproto, we are proud to serve as your full-service supply chain partner. That means we’re ready to take your product from prototype to production, and our start-to-finish support enables you to save both time and money, without compromising quality. With our custom part assembly services, you can expect a superior level of customer support and a dedication to ensuring optimal performance of your precision machined components.

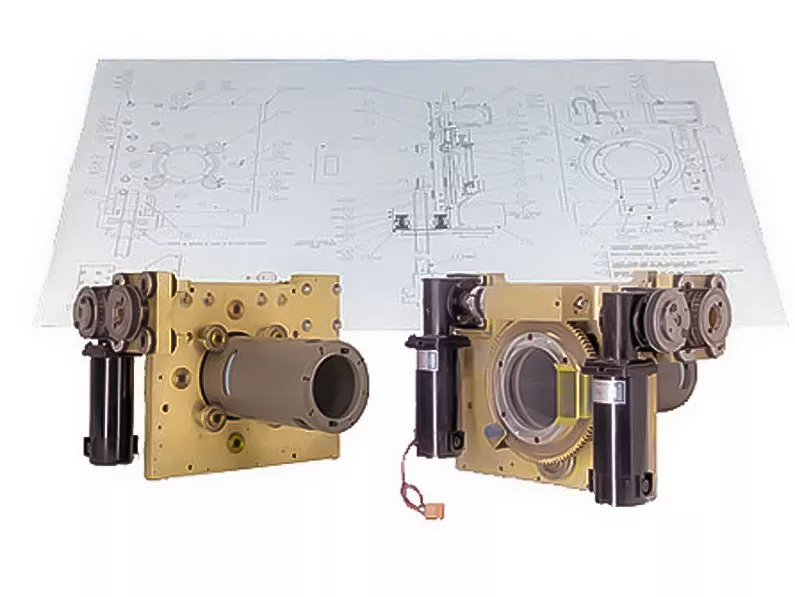

Complex Custom Component Subassembly

Xtproto’s subassembly service helps you achieve “one-stop” project success. Subassembly of complex multi-component parts is another advantage of Xtproto’s services, setting it apart in the custom manufacturing field. In addition to our professional custom parts manufacturing capabilities, we can also utilize pre-machined parts and supplier-supplied parts for precise and reliable assembly and subassembly, thus constructing complex components.

Our spacious manufacturing workshop is equipped with dedicated subassembly and testing rooms. We have experienced technicians committed to strict adherence to specifications and craftsmanship to create superior quality for you. In addition to timely and convenient turnkey services, our subassembly service offers advantages in quality control. Our comprehensive quality assurance system ensures 100% consistency, performing final functional testing on each assembled component and rigorously monitoring and recording the results.

Xtproto Custom Assembly Solutions

Focus on your core business and entrust assembly design and manufacturing to Xtproto. Our experts will select the best materials and components to ensure assemblies are durable, meet your unique specifications, and deliver optimal performance. From multiple part numbers and components to plug-and-play assemblies, we can design and manufacture any component that meets your application needs. Our expertise in a range of technologies and custom assembly services optimizes your supply chain, resulting in more efficient shipping, accounting, and auditing processes for our customers. Contact our custom assembly service experts today to discuss how Xtproto can help you maximize your workspace.

Why Choos Xtproto

Precision Alignment

Our skilled technicians meticulously align and assemble custom parts to exacting tolerances, ensuring that each component seamlessly integrates into the overall assembly. Precision is our hallmark, guaranteeing optimal functionality.

Customized Solutions

We understand that each project is unique. Our Custom Assembly Service is tailored to your specific requirements, accommodating diverse custom parts and configurations. Whether it’s a small prototype or a large-scale production run, we have the expertise to handle it.

Efficient Workflow

Xtproto’s assembly process is streamlined for efficiency. Our advanced facilities and skilled workforce enable us to manage assembly projects with agility, meeting deadlines without compromising on quality.

Quality Assurance

Rigorous quality control measures are integrated into every step of our assembly process. From initial component inspection to the final assembly, we uphold the highest standards to ensure the reliability and functionality of the end product.

We’re Experts at Putting Things Together

Optimize Production, Ensure Quality, & Meet Demand.Xtproto houses a wide range of state-of-the-art production equipment in a clean and well-organized facility, run by a dedicated, trained production team. When you partner with Xtproto for your assembly needs, you benefit from:

- Dedicated Work Cells

- A Mature ISO System

- A Vast Supplier Network for Parts & Materials

- Modern Facility with Dedicated Production Space

- 100% Complete Assemblies

- Automated Processes

- Tailored Quality Protocol

- Trained Production Teams

Assembly Processes

Solid Strategy aligned with business needs and robust data analysis are fundamental ingredients to extract actionable insights.

01. Design Overview

First, we take a close look at your design. This helps us spot any potential issues early on and ensures we have a clear plan before moving to the next stage, making the parts manufacturing and assembly smoother and more efficient.

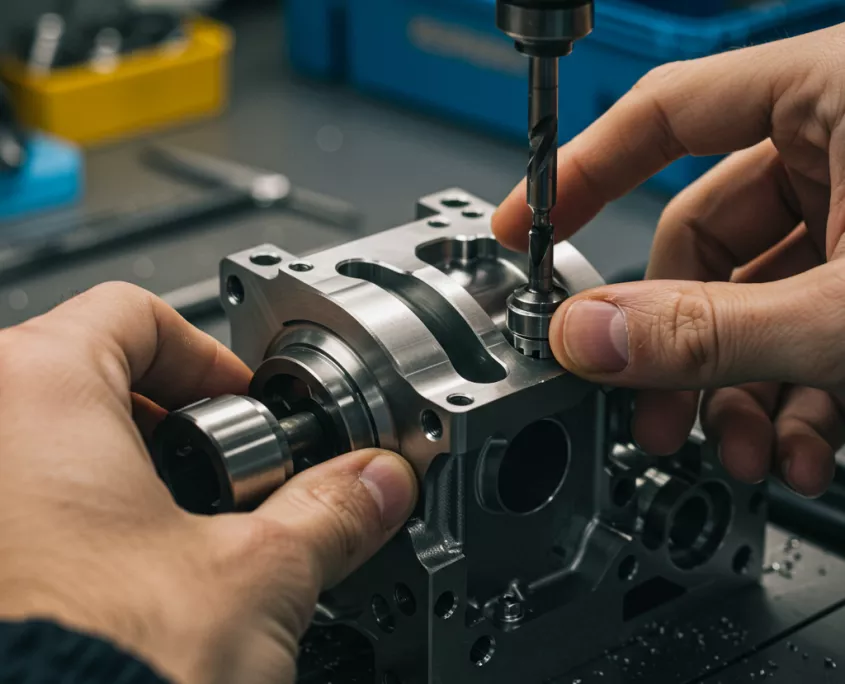

02. Part Preparation

Before coming together, every part is cleaned and inspected. By removing rough spots and verifying fit, we set the groundwork for a seamless assembly.

03. Assembly

Our skilled team assembles each component with precision. Using the best tools and part assembly process, we ensure all matal and plastic parts align correctly and function as intended.

04. Packaging & Delivery

Once complete, we pack your product with care, prioritizing its safety. We aim for prompt deliveries, getting your assembled item to you on schedule and in pristine condition.

Assembly Methods for Parts

Solid Strategy aligned with business needs and robust data analysis are fundamental ingredients to extract actionable insights.

Manual Assembly

Molding Assembly

Mechanical Assembly

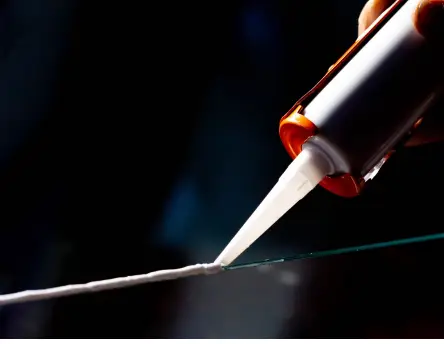

Adhesive Assembly

Assembly Inspection and QA

Xtproto provides industry-standard compliant testing solutions. Our testing services include:

- Standard Inspection

- Formal Inspection with Dimensional Report

- CMM Inspection with Dimensional Report

- First Article Inspection Report (FAIR AS9102)

- Source Inspection

- Custom Inspection

100% On-Time Delivery, Zero Defects

When quality and time are critical, at Xtproto, we see our business as an extension of yours. When you entrust us with desktop assembly services, from simple to complex, we tailor our production processes to your specific needs and standards. Our quality and production teams work hand-in-hand with you to establish quality control measures throughout the process; meanwhile, our logistics team handles daily, weekly, and monthly deliveries, allowing you to focus on other important matters.

Scalable to meet your needs

Leverage Xtproto’s support to fully utilize your production schedule. We’ll utilize your existing equipment or collaborate with you to develop new tooling and fixtures to ensure uninterrupted or delayed production, guaranteeing your products’ timely market launch. Our team can also work with you to develop custom-designed equipment for specific applications and continuously invest in new equipment to further enhance production efficiency.

Value-Added Packaging Services

Xtproto offers a wide range of assembly, packaging, and distribution services, including repackaging, sorting, counting, separating, material classification, material combination, bulk purchasing, and breaking down products into sales specifications. We also provide Just-In-Time (JIT) delivery services for all products.

Our extensive packaging options ensure effective solutions for every unique product. Packaging options include cartons, paper bags, shrink film, pallets, repackaging of original containers, bulk containers, and blister packs. Our advanced equipment ensures that every product is properly packaged to prevent loss and damage; our packaging, cutting, laminating, screen printing, and digital printing equipment, along with our ZED machinery and precision weighing scales, enable us to offer a diverse range of packaging solutions.

Start your project now!

We offer a range of assembly services and ensure quality with our comprehensive inspection services, guaranteeing you receive premium parts every time. Simply send us your 3D CAD files, and our customer service engineers will review your design to ensure its manufacturability, guaranteeing the parts meet your expectations and budget. Contact us today for a free quote!