CNC Machining

Custom manufacturing services for CNC machined parts, from one-off prototypes to full production runs. Turnaround in as little as 1 day. Request an online quote now.

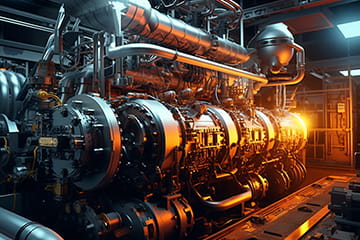

Xtproto's powerful CNC machine shop

Xtproto specializes in precision machining and CNC manufacturing, providing fully customized parts services for a variety of applications. With a 3,000 square meter facility, we have more than 180 skilled machinists and employees serving multiple customers around the world.

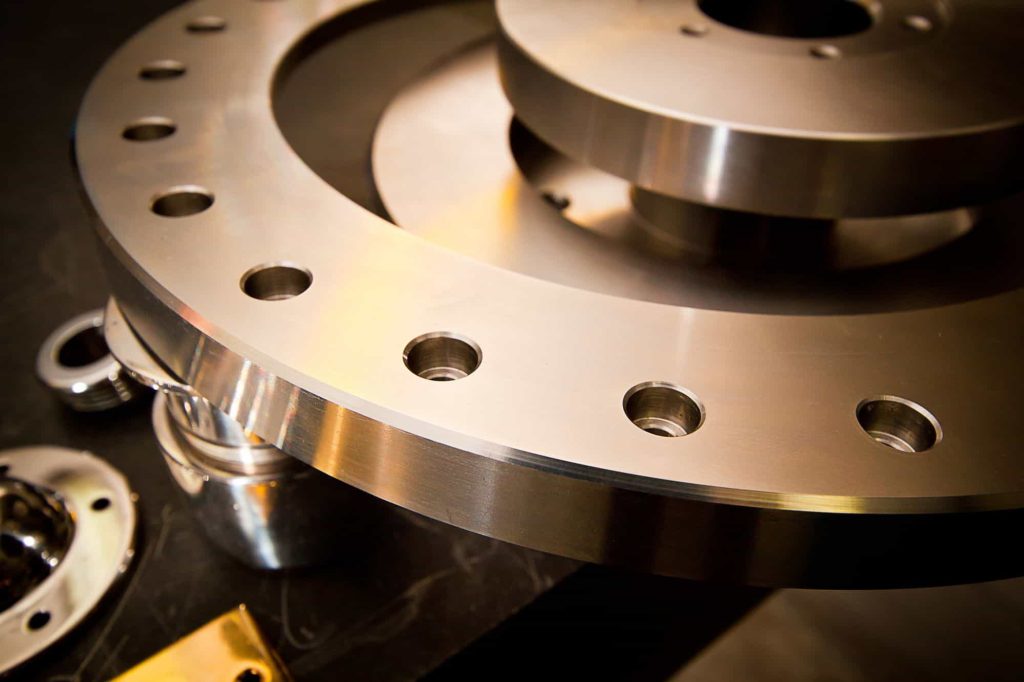

We are committed to precision component production and can achieve tight tolerances of ±0.0002 inches (5μm). Our expertise covers a wide range of machining services, including prototypes and production parts in a variety of metals and plastics. Whether you need a custom prototype or a modification to an existing design, our team is able to provide tailor-made precision components to increase production efficiency and optimize costs.

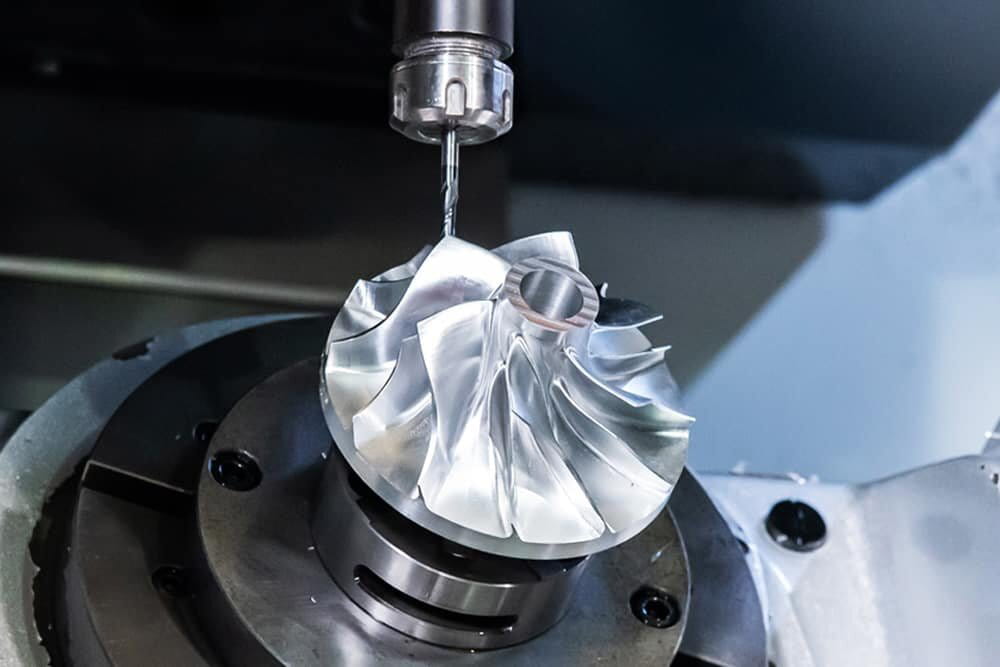

Our CNC shop uses advanced technology, including 4-axis and 5-axis CNC machines and precision testing instruments such as CMMs and Rockwell hardness testers, ensuring that each project meets the highest quality standards and achieves excellent surface finish. We are committed to providing precise solutions for both small batch and large-scale production needs.

Why XTPROTO?

- Perfect Precision: 3 and 5-axis machining with tolerances to ±0.001”

- Instant Quoting: Get pricing in seconds with our updated customer portal, XTPROTO

- Unconstrained Quantities, Size and Complexity: supporting you from prototyping to low, mid and high volume manufacturing

- Pre-production Review: Our standard ‘design for manufacturing’ review helps to mitigate potential issues, ensuring your parts meet your expectations

- Experience: Over 25 years of industry expertise. Our skilled CNC operators have an average of 10 years experience

- Outstanding Customer Service: More than 4000 satisfied customers

Our Custom Services

We are always ready to take on the challenge of tight tolerances and complex CNC machined parts. Perfect for designers and product developers looking to bring innovative ideas to life with top-notch custom components. Whether the project is simple or complex, our fully equipped machine shop is ready to take it on. Try our precision CNC machining services and become our next satisfied customer.

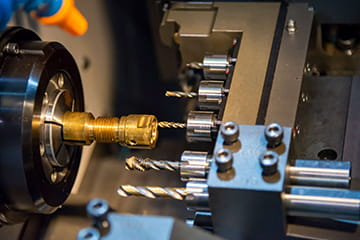

CNC Milling Services

CNC Turning Services

EDM and Wire Cutting Services

CNC Grinding Services

Swiss Machining Services

CNC Routing Services

5-Axis CNC Machining

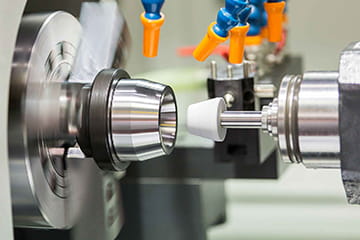

5-axis CNC machining allows complex parts with multiple side features to be machined on up to five sides in a single setup. This can pay huge dividends, increasing machine utilization, reducing setup and cycle times, and improving quality. 5-axis machining capabilities will make our CNC shop more cost-effective across a wider range of work.

CNC Machining Tolerances

- Maximum Part Size: Milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). Lathe parts up to 62” (1,575 mm) length and 32” (813 mm) diameter.

- General Tolerances: Tolerances on metals will be held to +/- 0.005″ (+/- 0.127 mm) in accordance with ISO 2768 unless otherwise specified. Plastics and composites will be +/- 0.010”.

- Precision Tolerances: XTPROTO can manufacture and inspect to tight tolerances, including sub +/- 0.001″ tolerances, per your drawing specifications and GD&T callouts.

- Minimum Feature Size: 0.020” (0.50 mm). This may vary depending on part geometry and chosen material.

- Threads and Tapped Holes: XTPROTO can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review.

- Surface Finish: The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote.

How we ensure the quality of your parts

- TS Prototype is equipped with high-precision, multi-axis CNC machines.

- We control tolerances according to ISO 2768. If you have specific tolerance requirements, please let us know.

- Equipped with a full range of testing instruments, such as coordinate measuring machines (CMMs), gauges, roughness testers, hardness testers, height gauges, etc. Each order is accompanied by a test report from our quality control department.

- We can provide other test reports upon your request.

- We are certified to ISO9001:2015, IATF 16949:2016, ISO13485:2016 and IEC27001:2013.

From concept to production: CNC machining in metals and polymers

Metal

- Aluminum

- Stainless steel

- Brass

- Copper

- Titanium

- Mild steel

- Alloy steel

- Tool steel

- Spring steel

- Bronze

- Steel

- Magnesium

Plastic

- ABS

- Polycarbonate (PC)

- Nylon

- Polypropylene (PP)

- POM

- PTFE (Teflon)

- PMMA (Acrylic)

- Polyethylene (PE)

- PEEK

- Bakelite

- Rubber

- Carbon Fiber

- HDPE

- HIPS

- LDPE

- PBT

- PPA

- PAI

- PET

- PPS

- PS

- PVC

- UPE

- Bakelite

- FR-4

CNC Machining Surface Finishes

Achieve the perfect surface finish with our range of surface finishes. Whatever type of surface finishing process you require, we can ensure your parts meet aesthetic and functional specifications.

- Standard (As-Milled)(Ra 125uin)

- Anodized

- Black oxide

- Bead Blast

- Spray painting – High gloss paint

- Powder coat – High gloss

- Galvanization

- Silver plating

- Tin plating

- Vacuum plating – Matt paint

- Smooth machining (Ra1.6um, 63 uin)

- Electrophoresis

- Etching

- PVD (Physical Vapor Deposition)

- Bead blast + Anodized color

- Electrically conductive oxidation

- Brushed

- Spray painting – Matt paint

- Powder coat – Matt

- Chrome plating

- Nickel plating

- Gold plating

- Vacuum plating – High gloss paint

- #1000 sanding

- Laser engraving

- Chemical conversion coat (Chem film)

- Passivation

- Electropolished (Ra0.8um, 32u

- Pickling

- Dyeing

- Silkscreen

- Others

CNC Machining: Is it right for your project?

01.

A Wide Range of Production-Grade Materials

From robust metals to intricate plastics, CNC’s material compatibility is vast, empowering your most ambitious designs.

02.

Greatest Degree of Dimensional Accuracy

Ideal for metal and plastic prototypes and production parts requiring the greatest degree of dimensional accuracy and critical surface finishes.

03.

Ideal for High Volume Production Runs

CNC machining’s automation and precision ensure consistent quality even at large scales, while its efficiency minimizes lead times and costs for high-volume production.

XTPROTO CNC Machining Solutions

Whether you’re creating a small batch of custom parts or scaling up for high-volume production, XTPROTO custom CNC machining services offer the flexibility you need.

Rapid Prototyping

Low Volume Manufacturing

End-use Production

What is CNC machining?

CNC, or computer numerical control machining, is a widely used manufacturing process that uses automated high-speed cutting tools to remove material from a metal or plastic workpiece until the desired geometry is achieved. Standard CNC machines include 3-, 4-, and 5-axis milling machines, lathes, and routers. Machines may differ in how they cut CNC parts – the workpiece may remain in place while the tool moves, the tool may remain in place while the workpiece rotates and moves, or the cutting tool and workpiece may move together. When a machinist receives a CAD (computer-aided design) model, also known as a 3D file, they begin by programming the tool paths based on the 3D file. Skilled machinists know how to optimize tool paths to reduce CNC machining costs and achieve tight tolerances.

Advantages Of CNC Machining Services

CNC machining offers many advantages for product developers, including:

- Fast material removal

- Tight tolerances and high precision

- Excellent for making complex geometries

- Versatile

- Suitable for many different kinds of substrates

- Unlimited volumes

- Low investment in tooling

- Fast turnaround

- Parts are full-strength

- Excellent surface finishes

- Easily customized

From Design to Delivery

At XTPROTO, we provide end-to-end solutions for the most challenging and complex components. From assisting with design, sourcing high-quality materials and precision CNC machining, to finishing, assembly and final delivery, we take care of everything.

Our customers receive finished parts, assemblies or private label products that are fully customized to their exact specifications. With our expertise, you can expect high-quality results, seamless project management and reliable on-time delivery.

Our own ISO-certified CNC machining facility delivers top-level quality and precision, backed by 24/7 technical support and a dedicated account manager for personalized service. We offer competitive pricing without compromising on excellence, making us the manufacturer of choice for customers around the world.

Request Your Free CNC Machining Quote Today

After receiving your drawings, our engineers will analyze your custom CNC machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.