Sheet Metal Fabrication

For product developers and buyers of custom sheet metal parts that need a high level of precision and require consistent on-time delivery of parts in days from their sheet metal fabricator. Sheet metal components and assemblies in as fast as 1 day. Get an online quote for your prototype or low-volume production project today.

Leading One-Stop Sheet Metal Fabrication Contract Manufacturer

XTPROTO is a leading multi-site contract manufacturing company headquartered in New Zealand. Since its inception, XTPROTO has been providing sheet metal fabrication services to a variety of clients and industries in domestic and international markets. We are a “one-stop” resource with a vertically integrated manufacturing facility that includes engineering design services, precision sheet metal, machining, electronic assembly, powder coating, painting, screen printing, final assembly and testing, and global logistics.

XTPROTO has earned a strong reputation for on-time delivery of quality products and a focus on customer service and support. With over 225,000 square feet of manufacturing space, we have the capacity to handle the most challenging jobs. We hold AS 9100 D:2016, ISO 9001:2015, and AS 9102 First Article Inspection certifications, which enables us to meet our customers’ requirements. In addition, our company holds SBA HUB regional certification and offers significant scalability for small to large multi-year contract production runs. Let the XTPROTO team provide you with solutions to your manufacturing challenges. We will demonstrate our extensive manufacturing capabilities, our passion for excellence, and our strategy to exceed your expectations.

Services We Provide

In-House Design

Manufacturing & Assembly

XTPROTO Sheet Metal Fabrication Capabilities

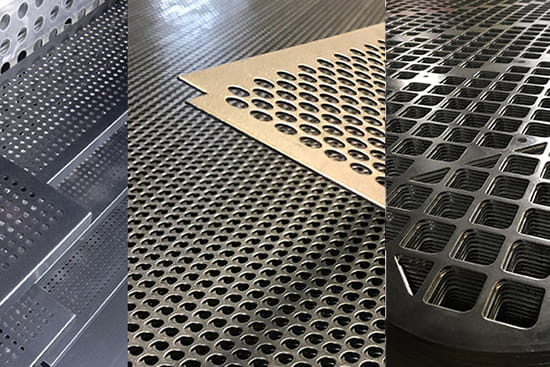

- Blank Size: 5’ x 10’ (1.52 m x 3.05 m). We accommodate larger part volumes upon request.

- Sheet Thickness: 0.024” – 0.250” typical. We accommodate thicker or thinner gauges upon request.

- Braking (Hydraulic): 14′ length

- Braking (Magnetic): 6 tons of magnetic pull across the entire beam, 5/8″ minimum reverse bend

- Punching: 2″ diameter hole capacity, or larger upon request

- Welding: Welded edges and seams, weldments, and assemblies

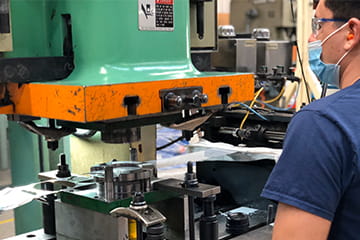

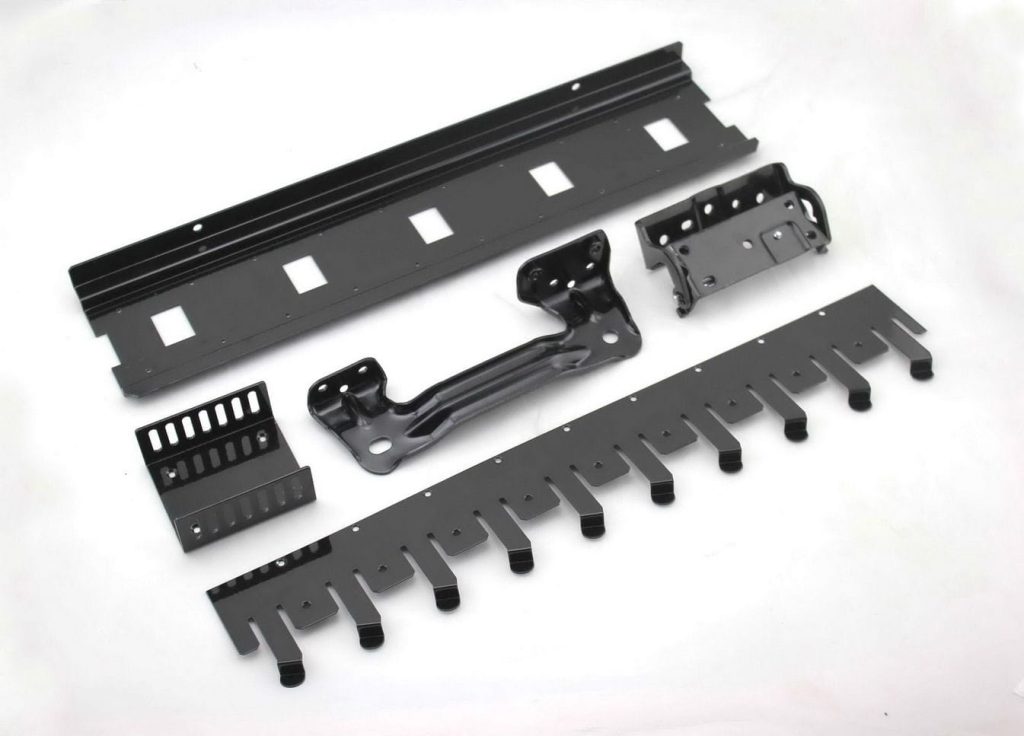

Sheet Metal Fabrication Services for Custom Parts

Choose XTPROTO for comprehensive online sheet metal fabrication services. With a wide range of advanced machines, including laser cutters, press brakes, and welders, we can handle everything from small batch prototypes to high volume production. Our team of sheet metal fabricators and knowledgeable engineers ensure that each sheet metal part is manufactured to precise specifications and quality standards.

Laser Cutting

Bending

Welding

Punching

Riveting

Stamping

Custom Sheet Metal Materials

XTPROTO offers a wide variety of sheet metal and fabrication materials to meet a variety of fabrication needs. Our team of skilled professionals is well versed in materials such as stainless steel, aluminum, and carbon steel. With our dedication to excellence and innovation, you can rely on our extensive expertise to turn your concepts and visions into reality.

- Aluminum

- Brass

- Bronze

- Copper

- Nickel Based High Temperature Alloys

- Inconel

- Invar

- Kovar

- Nitronic 60

- Stainless Steel

- Steel

- Titanium

- Tool Steel

Does your project require a material not on our list?

Let us know if your project requires materials that are not on the list! We can accommodate other material requests, but quotes may need more time while we source the material.

Sheet Metal Finishes

After cutting, bending, and forming sheet metal– finishing is the step in precision sheet metal fabrication because it determines the appearance and durability of the final product. Sheet metal fabricators may use various finishing techniques such as painting, powder coating, polishing, anodizing, or plating to provide additional protection against corrosion and wear. The chosen finishing technique depends on the metal product’s intended use and the designer’s aesthetic preferences. For example, a high-quality finish can enhance the product’s visual appeal and increase its value. Overall, finishing is crucial in creating a successful sheet metal fabrication project. Choosing a qualified and experienced sheet metal fabricator like XTPROTO can ensure the desired result is essential.

XTPROTO Sheet Metal Solutions

Rapid Prototyping

Low Volume Fabrication

High-volume Production

What Is Sheet Metal Fabrication?

The sheet metal fabrication process takes many steps and requires a team to complete the process. We usually use steel, aluminum, stainless steel, and similar metals for manufacturing, as the industries that use our services need reliable products.

Fabricating sheet metal involves stretching, cutting, and bending the metal to create the desired shape, thickness, and suitability for its intended application. Once it reaches these specifications, we weld it, rivet it or fasten it in place according to our customers’ needs.

How Does the Sheet Metal Fabrication Process Work?

The fabrication process uses specialized machinery to achieve the right specifications. For example, this machinery includes press brakes and cutting torches. We typically work with metals like steel, stainless steel, copper, brass, and aluminum, but our team has experience with many other materials.

The process begins with the design. We work with designs that you create from your blueprints and drawings that meet your exact specifications. Then, we cut the metal using techniques like shearing, roll forming, punching, blanking, metal stamping, and laser cutting.

Once we’ve cut the metal, we bend it into U, V, and L shapes. After we form all the pieces, we join them by welding, adhesives, riveting, fastening, or other methods best suited to the project. Finally, we apply a finish to the finished product to match your design.

Sheet metal fabrication leaves almost no room for error, and each step from cutting and bending to powder coating requires precision. Our quality processes mean that we catch and prevent mistakes early on, so you get uniform products every time.

Sheet Metal Fabrication & Contract Manufacturing

Our state-of-the-art equipment is designed to give our customers the highest quality product, and most are fully automated with unattended lights-out operations. On our fabrication floor we focus on Lean Manufacturing and Continuous Improvement every day. Our operational scalability and purchasing power help our customers face the challenges of demand fluctuations, design changes, short product lifecycles, and short lead times. Let us show you why so many companies have partnered with XTPROTO to consolidate their supply chain or add critical manufacturing capabilities.

Ready to Get a Sheet Metal Fabrication Quote?

XTPROTO’s sheet metal fabrication services deliver unmatched quality and precision to bring your project to life. With state-of-the-art equipment and a team of highly skilled technicians, we deliver outstanding results based on your specifications. Our commitment to innovation and attention to detail ensures your project is manufactured to the highest standards, meeting your timeline and budget requirements. Choose XTPROTO for your sheet metal fabrication needs and experience the difference our expertise can make.