Why Xtproto

We’re different. At Xtproto, we don’t just manufacture parts; we provide expert, white-glove support to help you navigate every stage of product development with precision and confidence. From concept to production, our experienced team of engineers will work closely with you to resolve issues early, accelerate your schedule, and ensure every part meets your exacting standards.

What sets Xtproto apart from others

Your projects will no longer be handled by algorithms or automated systems. Instead, you’ll receive hands-on guidance from real experts, starting with a personalized Design for Manufacturability (DFM) review to identify optimization opportunities. We’ll help you optimize part design, recommend ideal materials and processes, and coordinate production strategies to ensure you meet your goals on time and on budget.

When you work with Xtproto, you get a proactive digital manufacturing partner who’s committed to getting every detail right, because we understand the difference true collaboration makes.

Diverse Technical Capabilities

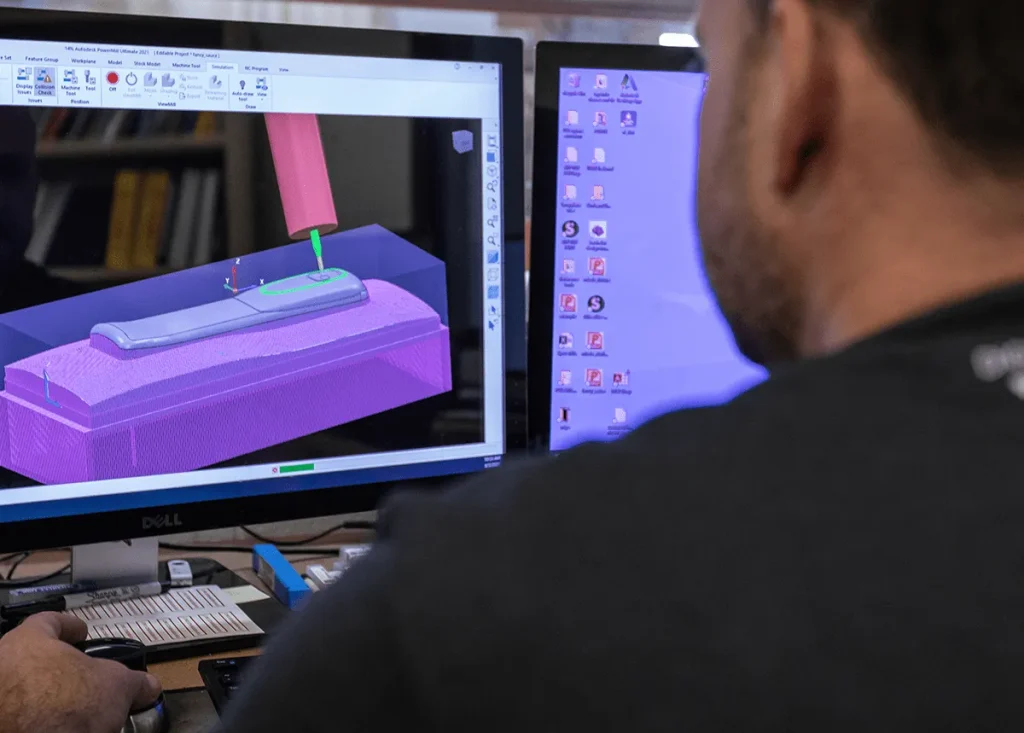

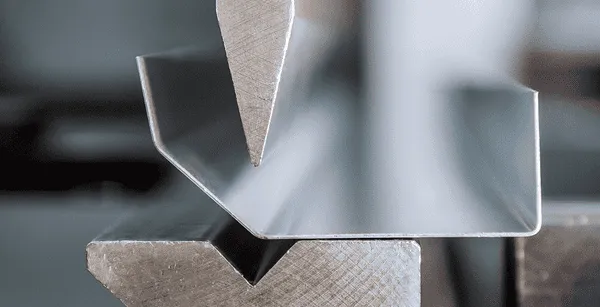

When developing a new part, the biggest challenge is often not just what to make, but how to make it. Selecting the right process, material, or production method can be overwhelming, especially when speed, cost, and quality are all crucial. That’s where Xtproto comes in. Whether you’re in the prototyping, scaled production, or somewhere in between, our engineers will work with you to evaluate your part design, identify opportunities for improvement, and guide you to the most efficient and cost-effective manufacturing path.

With a broad range of advanced manufacturing technologies and in-house experts, we can recommend a “best-fit” solution for each part, balancing performance, delivery time, and budget. With over 25 technologies, nine facilities, engineering support, and a variety of finishing services, Xtproto is able to meet more customer needs from a single source, streamlining their quoting, sourcing, and supply chain logistics processes.

Global Manufacturing Network

Xtproto’s in-house manufacturing network gives clients the flexibility to scale production across multiple locations globally, both offshore and nearshore, depending on the direction of their business. We maintain trusted partnerships with high-quality suppliers in major global manufacturing hubs and offer hybrid solutions that combine overseas production with local capabilities, depending on speed, cost, or complexity requirements.

Xtproto Network is our global sourcing solution. A fully managed, expert-led program designed to provide you with the lowest landed costs and local support. The Xtproto Network solution delivers smarter sourcing and a stronger supply chain through:

- Tariff-Smart Sourcing: HTS classification and tariff engineering are designed to minimize tariffs.

- End-to-End Logistics Management: We handle customs, duties, and freight, allowing you to scale production without worrying about costs, with domestic, international, and hybrid manufacturing options.

- Global Regulatory: Engineering and compliance experts manage every detail.

- White Glove Service: Single point of contact. Complete transparency. No surprises.

End-to-End Manufacturing Support

Bringing new products to market is never easy. From early design challenges to evolving production demands, manufacturers constantly need to balance speed, cost, risk, and performance. Xtproto’s end-to-end lifecycle support is designed to deliver real value.

Whether you’re developing a prototype or scaling up to production, our team will work with you to confidently navigate each stage, eliminating guesswork, identifying cost-saving opportunities, and ensuring manufacturing decisions align with your goals from day one. We offer flexible, scalable digital manufacturing solutions to support you at every stage:

- Design and Engineering Support: Provides Design for Manufacturability (DFM) analysis and material selection guidance.

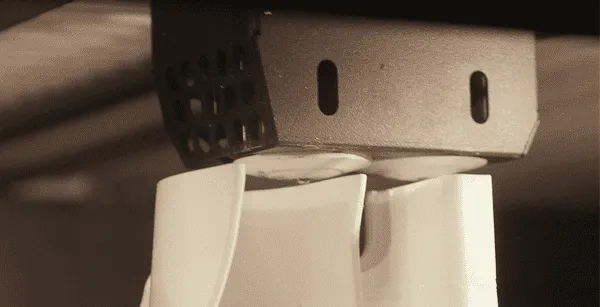

- Rapid Prototyping: Our deep expertise in prototyping helps you quickly optimize, iterate, and finalize part designs for production, so you can bring new products to market faster.

- Bridge and Low-Volume Production: Flexible solutions to meet diverse production needs.

- Flexible Production: Scalable manufacturing capabilities up to medium-volume production.

Our approach is ideal for teams working on low-volume, high-mix projects, or parts with complex geometries that don’t fit traditional high-speed models. We’ll contact you based on your specific situation and help you achieve your goals faster.

Xtproto's White Glove Service

Xtproto’s White Glove Service means more than just excellent customer support; it’s our commitment to expert guidance, proactive communication, and hands-on collaboration throughout the project lifecycle. Our dedicated team sets a new standard in an industry increasingly dominated by automated quoting systems and algorithm-driven design tools. Our human-centered engineering approach means every project is reviewed by real experts who work closely with your team to address issues early, recommend smarter alternatives, and guide design decisions to improve manufacturability, reduce costs, and accelerate time to market. We don’t just produce parts; we help you innovate with confidence.

When you work with us, White Glove Service means:

- Dedicated Engineering Support: We pair you with experienced engineers who stay involved throughout the project.

- Proactive Design, Function, and Function (DFM) Analysis: We help you optimize part designs early to avoid downstream issues.

- Clear, Consistent Communication: You’ll never be in doubt about the stage your project is in, as we keep you informed.

- Results-Driven Collaboration: We align with your goals and act as an extension of your team.

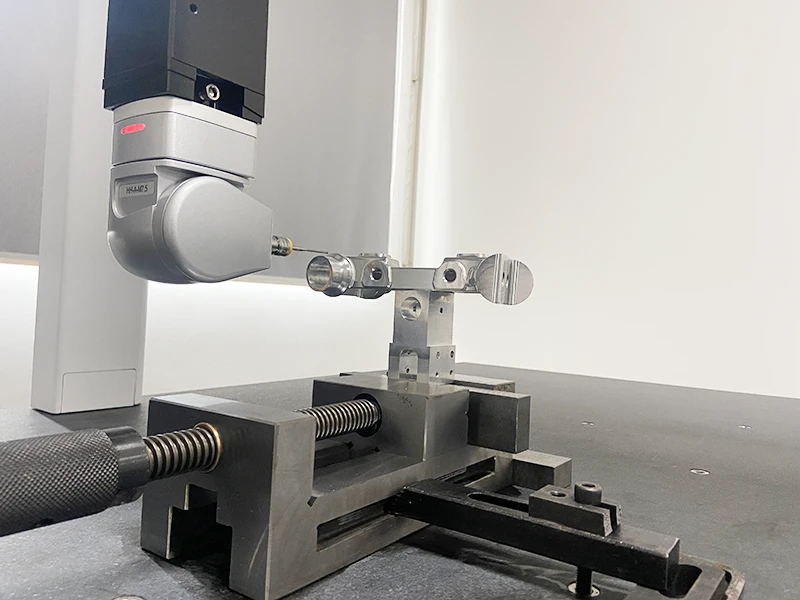

Certifications and Quality Assurance

We serve highly regulated industries such as medical, aerospace, and defense. These industries have some of the strictest quality requirements globally. But we’re up to the challenge. The Xtproto team understands that a rigorous quality management system (QMS) and accurate, comprehensive documentation are crucial to providing our customers with high-quality, compliant parts. Working with us, you can trust us to exceed your expectations and meet all relevant industry certifications.

All of our in-house facilities and international manufacturing network utilize a unified quality management system. This ensures that every part we deliver, regardless of origin, meets the same stringent requirements. Xtproto holds multiple certifications, including ISO 9001:2015 and ISO 13485:2016. Specific certifications vary by location.

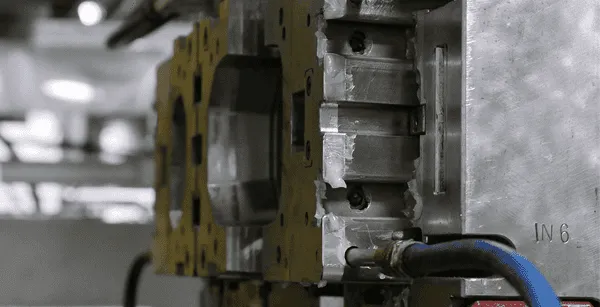

Xtproto Network Enhances Manufacturing Capabilities

The Xtproto Network unlocks expanded capabilities across our services. To scale your injection molding from small batches (10,000+ pieces) to high-volume production (100,000+ pieces), explore our network. CNC machining offers anodizing and tighter tolerances. Both molding and machining offer volume pricing options to reduce part costs. You can even create prototypes quickly and cost-effectively with FDM 3D printing. Leverage our digital network to get more out of your manufacturing.