What is slot milling?

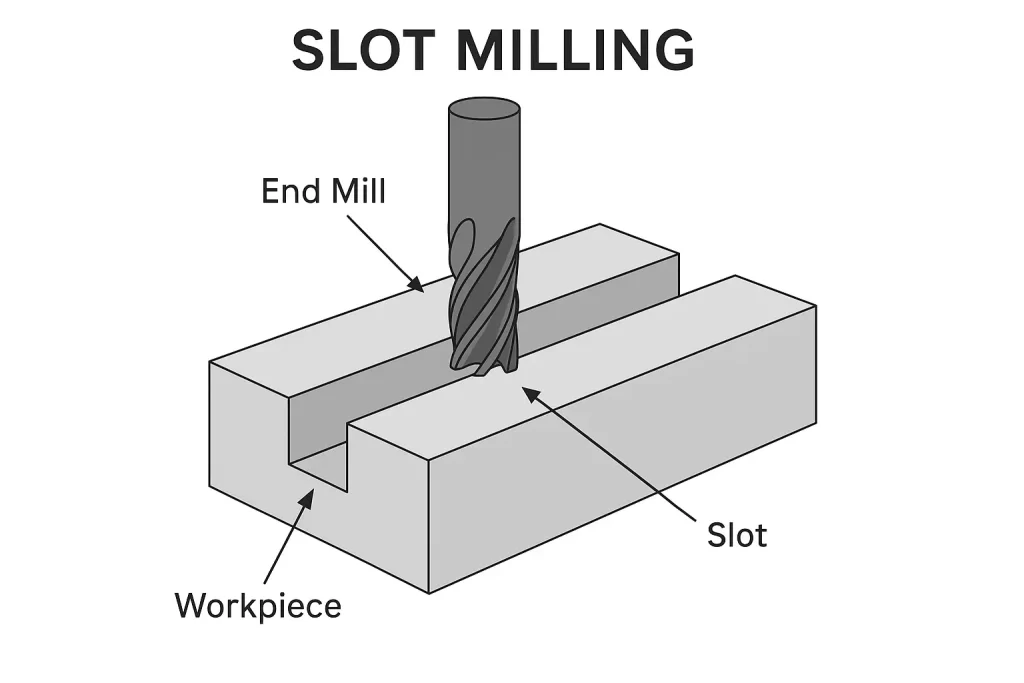

Slot milling is a specific CNC machining process used to create narrow, elongated features—such as straight slots, grooves, keyways, and T-slots—on a workpiece. These features are often required to hold keys, guide components, accommodate seals, or support other functional elements in mechanical designs.

While slot milling might seem similar to general milling techniques like end milling or face milling, it involves distinct tool engagement and machining strategies to ensure clean slot geometry and surface quality. Issues such as cutter entry method, chip evacuation, and tool selection play a larger role in slot milling than in more straightforward milling operations.

In this article, you’ll learn what slot milling is, how the process works, the types of slot milling technologies and cutters, practical applications, and best practices to achieve reliable results with modern CNC equipment.

What is slot milling?

A slot is a narrow channel machined into a workpiece to serve functional purposes such as housing fasteners, guiding mechanical parts, or enabling assembly.

Slot milling is the specific process of using a rotating cutter to create these features. Depending on design requirements, the resulting slots vary in complexity—ranging from simple straight grooves to intricate curved profiles or specialized undercuts.

History of slot milling

Slot milling dates back to the late 19th century, a time when the Industrial Revolution was in full swing. Back then, machinists used conventional milling machines (mostly horizontal ones) to manually cut the keyways needed for massive steam engine shafts. It was slow, high-pressure work, but these basic grooves were what made torque transmission possible in early engines.

By the 1950s, the process became more efficient with the arrival of arbor-mounted cutters and shell mills. This led to “gang milling”—a technique where several cutters worked at once to carve out multiple slots, like the T-slots you still see on machine tables today. It was a massive leap in productivity for large-scale factories.

The real “brain” was added in the 1980s with the rise of CNC slot milling. For the first time, operators could program complex motions like “ramp-down” entries and “plunge” cuts. This was a game-changer because it finally solved the age-old problem of chips getting stuck in deep slots, which used to snap tools constantly.

Since the 2010s, we’ve entered the era of “smart” machining. With adaptive toolpaths and trochoidal milling strategies, we no longer have to brute-force the material. These modern techniques, supported by high-speed CNC centers, have slashed cycle times by up to 50% while making tools last three times longer. Even with all these advancements, slot milling remains essential—it is still the go-to method for creating the precise channels that hold the modern world together.

How Does Slot Milling Work?

At its simplest, slot milling is about moving a rotating cutter along a path to remove material. But because the tool is often “buried” in the workpiece—cutting with its full diameter—the physics are much tougher than regular milling.

To get a perfect slot, the process follows three critical stages:

Planning and Tool Engagement

Everything starts with the slot’s dimensions (width, depth, and shape). Unlike side milling, where only a small part of the tool touches the metal, slotting involves full-width engagement. This means the tool is under pressure from both sides at once. To prevent the tool from bending (deflection) or vibrating, we use rigid fixturing and carefully calculated speeds.

Strategic Entry and Pathing

You can’t always just “dive” into a slot. We use specific entry methods like ramping (entering at an angle) or plunging (drilling down) to manage the initial impact. Once inside, the toolpath dictates how heat is spread. Instead of one heavy pass, we often use multiple shallow passes or modern “trochoidal” paths to keep the tool cool.

Chip Evacuation and Cooling

In a closed slot, metal chips have nowhere to go. If they aren’t cleared out immediately, the tool will “recut” them, leading to a rough finish or a broken cutter. This is why we use high-pressure coolant or air blasts to literally blow the chips out of the channel as they are created.

Finishing

The final step is the “finishing pass.” We leave a tiny bit of material during the rough cut and then come back with a clean pass to ensure the slot is perfectly smooth and hits the exact tolerances required.

Types of Slot Milling Techniques and Common Cutters

Slot milling isn’t a singular process; it’s a category of techniques defined by the slot’s geometry and the tool’s path. In professional CNC machining, the choice of technique is always dictated by the specific type of cutting tool used.

Full Slot Milling using End Mills

Full slot milling is the most common technique, where the cutting tool is engaged in the material across its entire diameter (100% engagement). It is the standard method for creating general grooves and channels.

- The Process: A standard end mill moves linearly to carve out the slot. Because the tool is “trapped” between two walls of metal, it faces the highest cutting forces and heat buildup.

- Best For: Shallow slots, roughing operations, and softer materials like aluminum or plastic where chip clearing is easier.

Side Slot Milling using Side and Face Cutters

Side slot milling is used for cutting deeper or longer slots that require more stability than a standard end mill can provide.

- The Process: Instead of a thin vertical tool, this uses a disc-shaped side and face milling cutter. These cutters have teeth on the periphery and both sides, allowing them to slice through material like a circular saw.

- Best For: Deep, narrow slots and applications where high-dimensional accuracy and excellent surface finish on the side walls are required.

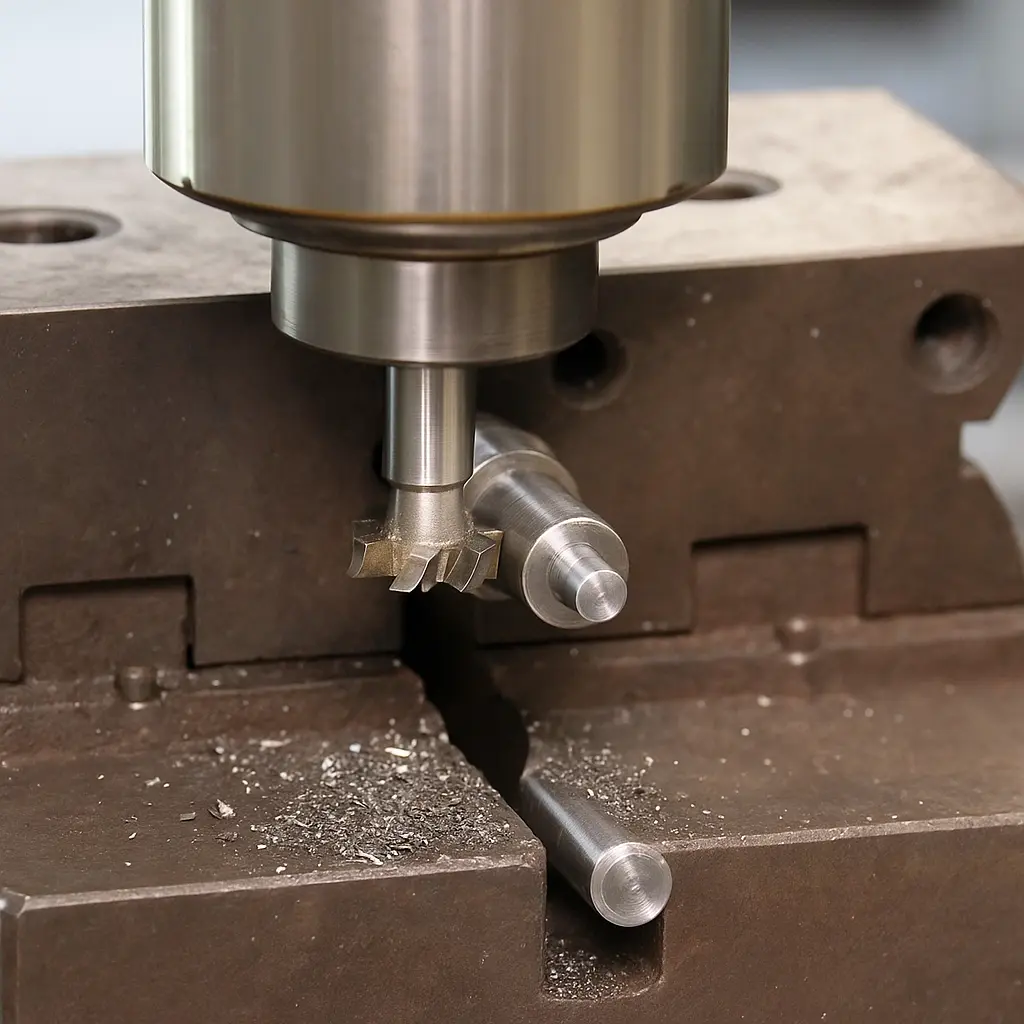

T-Slot Milling using T-Slot Cutters

T-slots are specialized features used for clamping and guiding. They cannot be machined in a single pass because the bottom of the slot is wider than the top opening.

- The Process: It is a two-step operation. First, a standard end mill cuts a “pilot” straight slot. Then, a T-slot cutter (which has a large head on a slim neck) performs the “undercut” to create the T-shape.

- Best For: Machine tool tables, fixture plates, and any sliding track system.

Keyway Milling using Woodruff Cutters

Keyway milling is a precision task used to create the slots that lock shafts and gears together.

- The Process: This technique uses a Woodruff cutter (a small, disc-like tool). The cutter is plunged into the workpiece to create a precise pocket that matches the shape of a Woodruff key.

- Best For: Power transmission shafts and mechanical assemblies that require exact alignment and torque handling.

Slot Milling Cutter vs. End Mill: What’s the Difference?

While they look similar, the choice between a standard end mill and a specialized slotting cutter depends on the precision and depth of your groove.

| Feature | Standard End Mill | Dedicated Slot Milling Cutter |

| Primary Use | General profiling, contouring, and facing. | Specifically for slots, keyways, and T-slots. |

| Flute Design | Often 4+ flutes for better finish in side milling. | Usually 2 or 3 flutes to provide more chip clearance. |

| Cutting Width | Flexible; used for various widths. | Fixed width; designed for “one-pass” precision. |

| Rigidity | General purpose. | Higher radial rigidity to prevent tool deflection. |

Pros and Cons of Slot Milling

Understanding the ‘Pros and Cons’ of slot milling is essential for optimizing your design. We’ve broken down the key factors—from accuracy to heat management—that determine the success of a slotting operation.

| Category | Advantages (Pros) | Disadvantages (Cons) |

| Precision | High Accuracy: Can achieve tight tolerances (up to $\pm$0.01mm) for press-fit parts. | Tool Deflection: High cutting forces can cause the tool to bend, affecting verticality in deep slots. |

| Geometry | Extreme Versatility: Capable of complex paths—curved, T-shaped, or helical slots. | Depth Limits: Efficiency drops significantly when the depth exceeds 3x the tool diameter. |

| Material | Universal Compatibility: Works on everything from soft plastics to tough Titanium/Inconel. | Tool Wear: Confined spaces trap heat, which accelerates wear on the cutting edges. |

| Cost & Speed | Low Setup Cost: Uses standard tools; perfect for prototypes and small batches. | Chip Evacuation: In deep slots, chips can get trapped and re-cut, risking damage to the surface finish. |

Best Practices for Slotting

Slotting may seem simple in theory, but machinists often face many challenges when slotting. To ensure a successful milling operation, we recommend the following best practices.

Optimize tool entry with ramp milling

Sudden entry into the workpiece can cause shock to the tool, causing it to break or deform. Ramp entry (gradually lowering the tool at an angle) is recommended to evenly distribute cutting forces. A 45° ramp entry angle is sufficient to prevent tool overloading. For deep slots or hard materials, an 180° axial entry similar to drilling can reduce radial forces and prevent tool overloading. This approach not only prolongs tool life, but also avoids the catastrophic consequences of tool breakage during the entry process.

Chip evacuation strategy

Chips stuck in the slot can re-enter the workpiece or clog the chip vent, affecting surface finish. One way to address this problem is through multi-pass milling. Remove material in layers (for example, roughing to 70% of the depth first, then finishing). This allows room for the chips to evacuate from the slot wall. Another option is to use an end mill with a serrated edge or variable helix angle to break the chips into manageable pieces. Use high-pressure coolant or compressed air to flush the chips, especially in closed slots.

Use larger diameter tools

Given the higher cutting forces and deeper slots, a larger diameter milling cutter is needed to prevent deflection caused by the long overhang. The larger the diameter, the greater the strength, which is ideal for this particular operation.

Up and Down Milling

Climb milling (cutters rotate in the same direction as feed) is the preferred method for slotting operations. Climb milling reduces tool wear and improves surface finish because cutting forces push the workpiece downward, minimizing vibration. This is useful for thin-walled parts or materials that are prone to burring.

Spindle Engagement

Interrupted cuts leave pits on the slot surface, resulting in poor surface quality. It also wastes time and does not speed up the process. To avoid this, make sure at least one tooth of the milling cutter is always in the workpiece.

Applications of slot milling

Slot milling is essential whenever parts need to slide, lock, or seal. Here is where it is most commonly used:

Automotive: Keyways for drive shafts, transmission gears, and O-ring grooves in engine blocks.

Aerospace: Weight-reduction channels in airframes and cooling slots in turbine components.

Industrial Machinery: T-slots for machine tool tables and sliding tracks for heavy-duty fixtures.

Electronics: Heat sink fins and EMI shielding paths in aluminum enclosures.Medical Devices: Guide channels for surgical instruments and locking mechanisms for orthopedic implants.

How can Xtproto help?

Designing a product that requires linear slots to be milled? Or need a custom part with tight tolerances? Contact Xtproto for precision CNC milling services. With 3-, 4-, and 5-axis milling capabilities, we can easily handle even the most complex or delicate designs. Whether you need rapid prototyping or high-volume production, we can ensure the slot accuracy of your product (metal, plastic, or alloy). Get a quote now. Simply send your design to Xtproto’s backend and our experts will turn your vision into reality!

Frequently Asked Questions

What tools are used for slot milling?

Common tools used for slot milling include end mills, slot drills, and T-slot cutters. End mills are used for standard slots, while T-slot cutters are designed for undercut features. Tool selection depends on slot width, depth, material type, and required surface finish.

What is the difference between groove milling and slot milling?

Groove milling and slot milling are closely related machining operations and are sometimes used interchangeably. Slot milling typically refers to cutting full-width slots with significant tool engagement, while groove milling often describes shallower or narrower cuts made along a surface. In practice, the difference mainly depends on groove depth, width, and application rather than a strict technical definition.

What is the process of T-slot milling?

T-slot milling is typically performed in two steps. First, a straight slot is machined using an end mill. Then, a T-slot cutter is used to undercut the bottom of the slot, forming the characteristic T shape. This process is commonly used for machine tables, fixtures, and clamping systems.

What tools are used for slot milling?

Common tools used for slot milling include end mills, slot drills, and T-slot cutters. End mills are used for standard slots, while T-slot cutters are designed for undercut features. Tool selection depends on slot width, depth, material type, and required surface finish.