How to determine whether a project is suitable for casting or machining?

There are many ways to manufacture metal and alloy components, and choosing the right manufacturing method depends on factors such as material type, part design, production volume, and performance requirements. Among these options, casting and machining are two of the most commonly used metal manufacturing processes, and selecting between them is often a key decision point for engineers, designers, and manufacturers.

Machining is a subtractive process that removes material from a solid workpiece to achieve the desired shape and dimensions, while casting involves pouring molten metal into a mold and allowing it to solidify into the final form. Each process offers distinct advantages and limitations in terms of cost, precision, design flexibility, and production efficiency.

In this article, we will compare casting vs machining by examining their working principles, advantages, disadvantages, and key differences. This will help you better understand when to choose casting, when machining is more suitable, and how to select the right process for your specific project requirements.

What is Casting?

Casting is a metal manufacturing process in which molten metal is poured into a mold cavity with a predetermined shape. After the metal cools and solidifies, it forms the desired part. Molds may include cores and inserts, allowing casting to produce complex geometries and internal features that are difficult or inefficient to achieve through machining.

Casting can be applied to both ferrous and non-ferrous metals and is widely used to manufacture parts of various sizes and shapes across many industries. It is particularly suitable for producing complex components and high-volume parts where cost efficiency becomes critical.

Casting has a long history that can be traced back more than 4,000 years to early metalworking in Europe, and today it remains one of the most mature and reliable metal manufacturing processes in modern industry.

What is machining?

Machining is a manufacturing process that removes material from a solid workpiece using cutting tools to achieve the desired shape, dimensions, and surface finish. The tool or workpiece follows a controlled path until the required size and accuracy are reached.

In CNC machining, these operations are controlled by computer programs, ensuring high consistency and repeatability. Common machining processes include turning, milling, drilling, grinding, and electrical discharge machining (EDM), which are performed using equipment such as CNC lathes, milling machines, and drilling machines.

Machining is particularly suitable for producing high-precision components, tight-tolerance parts, prototypes, and low- to medium-volume production. Because the process is driven directly by CAD and CNC programs, machined parts can closely match design specifications without the need for tooling.

Machining has evolved significantly since its early development in the 17th century and advanced rapidly with the introduction of numerical control and CNC technology in the mid-20th century. Today, CNC machining remains one of the most accurate and flexible manufacturing processes in modern industry.

How Casting vs. Machining Works

Casting and machining differ fundamentally in how material is shaped and how parts are produced. Casting forms components by solidifying molten metal in a mold, while machining removes material from a solid workpiece using cutting tools. Understanding how each process works helps explain why they are suited to different design, precision, and production requirements.

How does casting work?

Casting works by melting metal and pouring it into a mold cavity with a predefined shape. The molten metal fills the mold and solidifies, forming the final part. Depending on the process, molds may include cores to create internal features.

Once solidified, the casting is removed from the mold and may undergo secondary operations such as machining or surface finishing to meet dimensional and quality requirements. This ability to form complex shapes in a single step makes casting especially suitable for complex geometries and high-volume production.

How does machining work?

CNC machining is a computerized manufacturing process where software and code control the operation of the machine. The CNC machining process is subtractive machining, which is shaping an object by removing material from the workpiece until the desired parameters are achieved.

Design engineers input complex models into specialized software, which then outputs code that controls the CNC machine. The machine makes parts based on the constraints listed by the programmer in the software. The software automatically generates tool paths, cooling rates, feed rates, and various other parameters to make the part using the materials specified by the design engineer.

The coding language for CNC machines is called G-code. Creating a machined part involves rendering a computer-aided design (CAD) and converting it into computer-aided manufacturing (CAM) software. The CAM software then converts the tool paths for the CNC machine. After entering the program, the operator does a test run to find and correct any errors.

The process works with a variety of materials, including metals, plastics, wood, composites, glass, and foam. Each part requires a specific computer program to ensure tight tolerances, processing speeds, tool life, surface finish, and more.

Advantages and Disadvantages of Casting

Casting is widely used in metal manufacturing due to its ability to form complex shapes and support mass production. However, it also comes with certain limitations that may affect cost, precision, and lead time. The table below summarizes the key advantages and disadvantages of casting.

| Advantages | Disadvantages |

| Simple for complex parts: Using a cross-die setup, you can cast complex metal parts with hollow sections and irregular contours. | Prone to defects: Casting parts are prone to defects such as porosity, shrinkage, warping, and surface cracks. These defects are mainly caused by incorrect process parameters and poor quality of raw materials. |

| Material diversity: Scrap and low-grade metals/alloys can be used to cast metal parts as long as the molds and equipment can withstand the melting point. | Labor-intensive: Especially when comparing casting and machining, metal casting technology requires more labor from pouring to ejection. |

| High-volume production is cost-effective: Once you invest in molds and tooling, it can produce up to millions of identical items, reducing the casting cost of each part. | Harmful emissions: The melting and processing of waste produces harmful emissions such as CO, VOC and metal fumes. |

| Dimensional flexibility: Techniques such as sand casting and investment casting can cast parts up to several meters in size, while die casting methods are flexible and can cast parts up to 300 x 650 mm or larger. | High tooling cost and long setup time: Casting requires molds, patterns, or dies that involve high upfront costs and long lead times. This makes casting less economical for prototypes or low-volume production. |

| Incorporation of inserts: To create parts with multiple materials, pre-made inserts can be incorporated into the casting, such as bimetallic bearings. | Lower dimensional accuracy and reliance on secondary processing: Casting generally provides looser tolerances and inconsistent surface finish compared with machining. As a result, secondary machining or finishing operations are often necessary to achieve precise dimensions. |

Advantages and Disadvantages of Machining

Machining is known for its precision and flexibility, especially in low-volume and high-accuracy applications. The following table summarizes the key advantages and disadvantages of machining.

| Advantages | Disadvantages |

| High precision: Multi-axis CNC machines can provide tolerances as low as ± 0.001”, even for complex items such as turbine blades and medical components. | Internal Features Are Difficult to Machin: Machining is challenging for complex internal geometries such as deep cavities and channels. |

| Fast production of small batches: Unlike casting, it does not require a large number of tools, which makes prototypes and small batches simpler and faster. | Size Limitations: Large parts and products are challenging due to spindle motion limitations. |

| Excellent repeatability: CNC setups can use CAD models and CNC The program creates parts that are identical in size, finish, and quality. | Material Waste: The process of removing material to achieve the designed geometry includes debris and dust. |

| Highly automated: The CNC machining process enables automated production, reducing human errors and labor costs. The machine operates around the clock, increasing efficiency. | Higher tooling and machine costs: Machining requires expensive CNC machines, cutting tools, and fixtures, increasing capital and operational costs. |

| Range of materials: In addition to metals, it is also suitable for plastics, composites, and ceramics. | Longer cycle time for complex or high-precision parts: Parts with intricate features or tight tolerances take more time and multiple operations to machine, reducing throughput. |

Machining Vs Casting: Types and Techniques

Both casting and machining have different types and technologies covering a vast range of possibilities in manufacturing; the following is an explanation of the different machining technologies for the two processes

Types of Machining Technology

Milling, turning, drilling, and grinding are the main machining operations These operations differ in the types of tools they are compatible with, how the tools move, and application preferences.

- Milling: Milling involves a rotating tool mounted on a spindle that moves along multiple axes to shape the workpiece material. This type of machining is versatile and suitable for complex designs. Machine tools with 4, 5 or more axes are often used for machining automotive chassis, orthopedic implants, and injection molds.

- Turning: During turning, the workpiece rotates at a determined speed and the tool feeds the material, forming axisymmetric shapes such as cylindrical and conical shapes. CNC lathes are suitable for this type of machining.

- Drilling: Drilling is used to machine circular holes, where a twist drill bit rotates and feeds the material using multiple cutting edges. Hole diameter (⌀) Depends on the diameter and length of the drill. CNC drilling is suitable for aluminum, stainless steel, copper, plastics, and thermosets. Meanwhile, drilling in hard materials such as titanium alloys requires carbide or tungsten alloy drills.

- Grinding: Grinding refines the surface of a part to the desired dimensional tolerance and surface quality. A grinder uses a rotating grinding wheel to remove small amounts of material. Also, CNC grinding can achieve a roughness of 3.2 to 0.3 µm.

Types of Casting Techniques

You can choose from different types of casting, which are classified based on the structure of the mold or die used to cast the metal.

- Sand casting: This method requires making a mold out of silica sand, green sand, or other fine sand, and forming a cavity by placing a pattern, compacting the sand around the pattern, and removing the pattern. Sand casting molds can be used for single or multiple cycles and are suitable for high-melting-point metals.

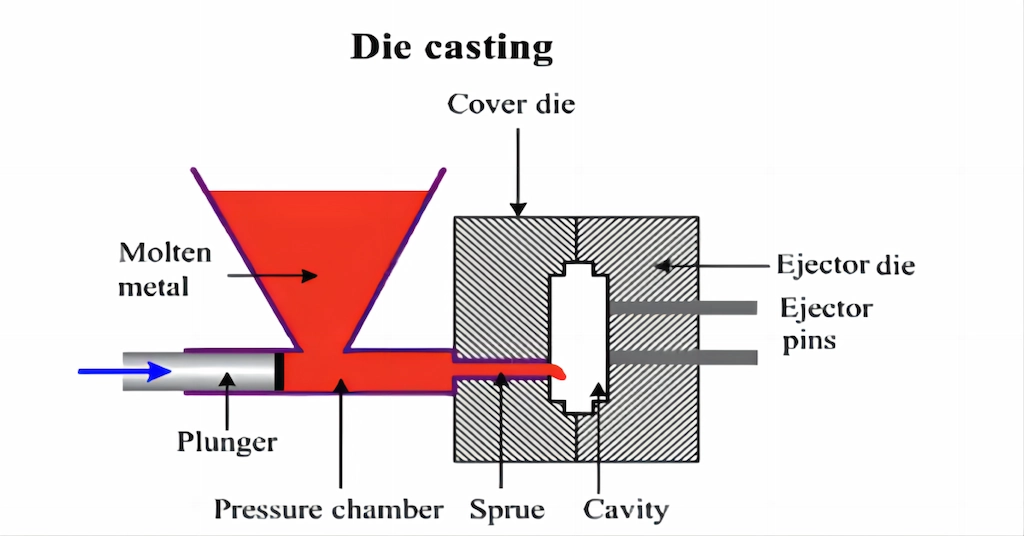

- Die casting: Die casting is an advanced and popular method for mass production of non-ferrous metals. The mold is made of tough and thermally stable materials such as stainless steel. At the same time , milling, turning, EDM and other precision CNC machining technologies can make reusable die casting molds.

- Investment casting: This metal casting process requires the use of a wax pattern coated with refractory materials and binders. Then, after pouring the molten metal, the wax pattern is immediately replaced with the wax pattern to shape the part/product. Investment casting can make replicas of large and complex models, such as turbine parts. Therefore, this is mainly suitable for prototyping and small batch production.

Main differences between machining and casting

The table below compares machining and casting across key technical and production factors to help determine which process is better suited for different manufacturing requirements.

| Aspect | Machining | Casting |

| Tools | Uses cutting tools such as end mills, drills, face mills, and milling cutters operated on CNC machines | Requires more comprehensive tooling, including patterns, molds, cores, and mold-making equipment |

| Precision and Accuracy | Provides high precision and tight tolerances, in some cases as precise as ±0.0025 mm | Generally lower accuracy, though precision casting methods such as die casting can achieve tolerances around ±0.10 mm with high repeatability |

| Material Compatibility | Suitable for metals as well as non-metallic materials such as plastics, composites, ceramics, and wood | Material compatibility depends on the casting process; sand casting suits ferrous metals, while die casting is mainly used for non-ferrous metals |

| Design Complexity and Size | Ideal for parts with sharp edges, fine details, and complex external geometries; part size is limited by machine capacity | Better suited for complex internal structures and large or thick-walled components |

| Production Volume and Speed | Well-suited for prototypes and low- to medium-volume production with fast setup and turnaround | More efficient for high-volume production once molds are prepared |

| Part Strength | Produces parts with uniform internal structure and consistent mechanical properties | Can maintain near-original metal strength through controlled solidification and can be enhanced by heat treatment |

| Prototype Suitability | Excellent for rapid prototyping using CAD models with minimal tooling investment | Prototyping is slower due to mold requirements, though processes like investment casting can be competitive |

| Production Cost | Lower initial cost and economical for small to medium batches | Higher tooling and setup costs, but lower unit cost in large-scale production |

Typical Applications of Casting and Machining

Because casting and machining differ in design flexibility, production volume, cost structure, and tolerance capability, each process is preferred in specific industries and applications. Understanding where casting and machining are commonly used helps manufacturers select the most efficient and cost-effective manufacturing method.

Typical Applications of Casting

Casting is commonly used for large, complex parts and high-volume production where near-net-shape manufacturing is beneficial.

Typical casting applications include:

- Automotive: Engine blocks, cylinder heads, wheel rims, suspension and transmission housings

- Aerospace: Engine housings, turbine blades, structural components

- Medical: Equipment frames and structural bases for medical devices

- Industrial machinery: Valve bodies, pump housings, gearboxes, heavy equipment frames

- Consumer goods and construction: Cookware, decorative products, pipes, fittings, and architectural components

Typical Applications of Machining

Machining is preferred for high-precision components, tight tolerances, and low-volume or customized production.

Typical machining applications include:

- Automotive: Gears, pistons, crankshafts, brake components

- Aerospace: Turbine discs, fasteners, hydraulic parts

- Medical: Surgical instruments, implants, precision medical components

- Industrial machinery: Precision gears, shafts, bearings, tooling components

- Electronics and consumer devices: Precision connectors, micro-components, housings.

Casting vs. Machining: Which Manufacturing Process Is Right for Your Project?

When deciding whether a manufacturing project should be cast or machined, it is important to evaluate the part design, production requirements, and overall cost considerations. The following key factors can help determine which process is better suited for your application.

- Production volume: Production volume is one of the most important factors when choosing between casting and machining. CNC machining is well suited for prototypes and low-volume production, as it requires no molds and offers flexible design changes. Casting processes, on the other hand, are more economical and scalable for medium- to high-volume production once the tooling is prepared.

- Part Complexity and Size: Part geometry plays a critical role in process selection. CNC machining is ideal for parts with fine details, tight features, and complex external contours, especially when micro tools are used. Casting is better suited for large parts or designs with complex internal structures that would be difficult or inefficient to machine.

- Accuracy and Repeatability Requirements:Machining offers higher dimensional accuracy and tighter tolerances, making it ideal for precision components. Casting generally provides better repeatability in mass production, as the same mold can be used consistently across multiple cycles. Before selecting a process, it is important to determine whether precision or repeatability is the primary requirement.

- Material Selection: The material used in production is also important. Casting has fewer material options, while there are a wide variety of machinable materials. Metals with high melting points are difficult to die cast.

- Material waste: Waste not only increases material costs, but also makes it difficult to recycle materials. Therefore, it is necessary to determine how much material will be wasted in the workpiece during machining. On the other hand, if the casting process is used, , there is little material waste.

- Production Speed:Production timeline can influence the final decision. CNC machining is faster for prototypes and small batch production due to minimal setup requirements. For medium to large production volumes, casting becomes faster and more efficient once molds are in place.

In general, machining is preferred for high-precision parts, rapid prototyping, and low-volume production, while casting is better suited for large, complex components and high-volume manufacturing.

Conclusion

Choosing between casting and machining depends on part design, performance requirements, and production volume. Machining is typically used for high-precision parts and low- to medium-volume production, while casting is better suited for large, complex components and high-volume manufacturing. In many cases, combining casting with secondary CNC machining offers an efficient balance of cost, accuracy, and quality.

Xtproto provides CNC machining, metal casting, and vacuum casting services to support both prototyping and production needs.